12/4/2024

Effective waste management is essential to minimize expenses and enhance overall operational efficiency. One promising approach is reclaiming valuable components from waste streams, thereby reducing the volume of hazardous waste requiring disposal. With the high cost and difficulty of landfill disposal significantly impacting profitability in industrial processes, industries can reclaim valuable components from waste streams, thereby reducing disposal costs and improving process efficiency. In our experience the approach described can solve the issue, highlighting the importance of innovative waste management solutions in enhancing profitability and sustainability. For industries facing similar challenges, looking at reclaiming valuable materials from your waste stream can lead to significant improvements in waste management, ensuring a more sustainable and profitable future.

9/22/2024

Thin film evaporation technology presents several advantages in the process of silicone purification. Notably, this method offers rapid removal of volatile components to parts-per-million levels within a scalable and environmentally friendly equipment package.

8/25/2024

Carbon capture technology is the next step in addressing climate change by reducing the amount of carbon dioxide (CO2) released into the atmosphere from industrial sources. Among the various methods employed, the use of catalysts and absorbents has shown significant promise. These methods leverage the properties of specific materials to enhance the capture and storage of CO2, thereby improving efficiency and effectiveness.

5/28/2024

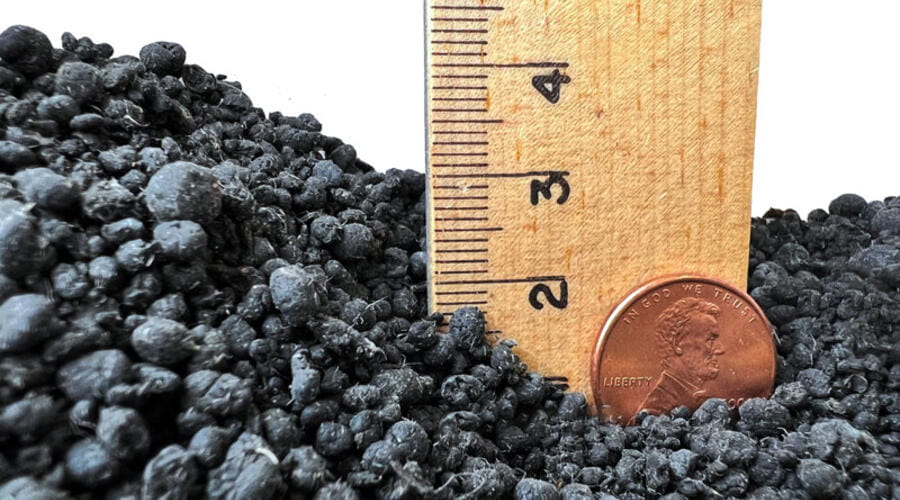

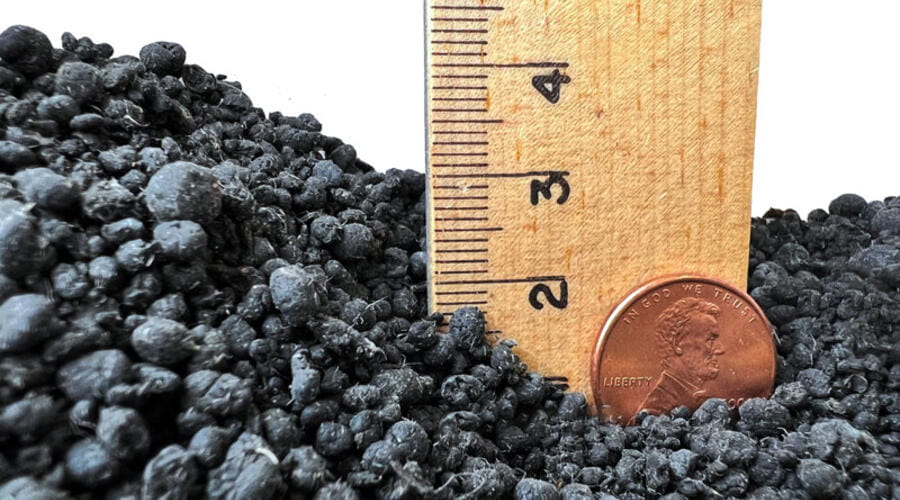

Low pressure extrusion is a manufacturing technique that has been widely used in a variety of industries. LCI has been providing low pressure extrusion systems for over 40 years. Excellent control and process repeatability make this process well suited for manufacturing consistent and quality granules.

5/28/2024

Generation of biofuels such as Renewable Natural Gas (RNG) and Sustainable Aviation Fuel (SAF) are becoming more common as we look to reduce our climate impact. Thin film technologies are a perfect fit in these processes to reduce moisture content, concentrate solutions, and recover valuable solvents.

4/3/2024

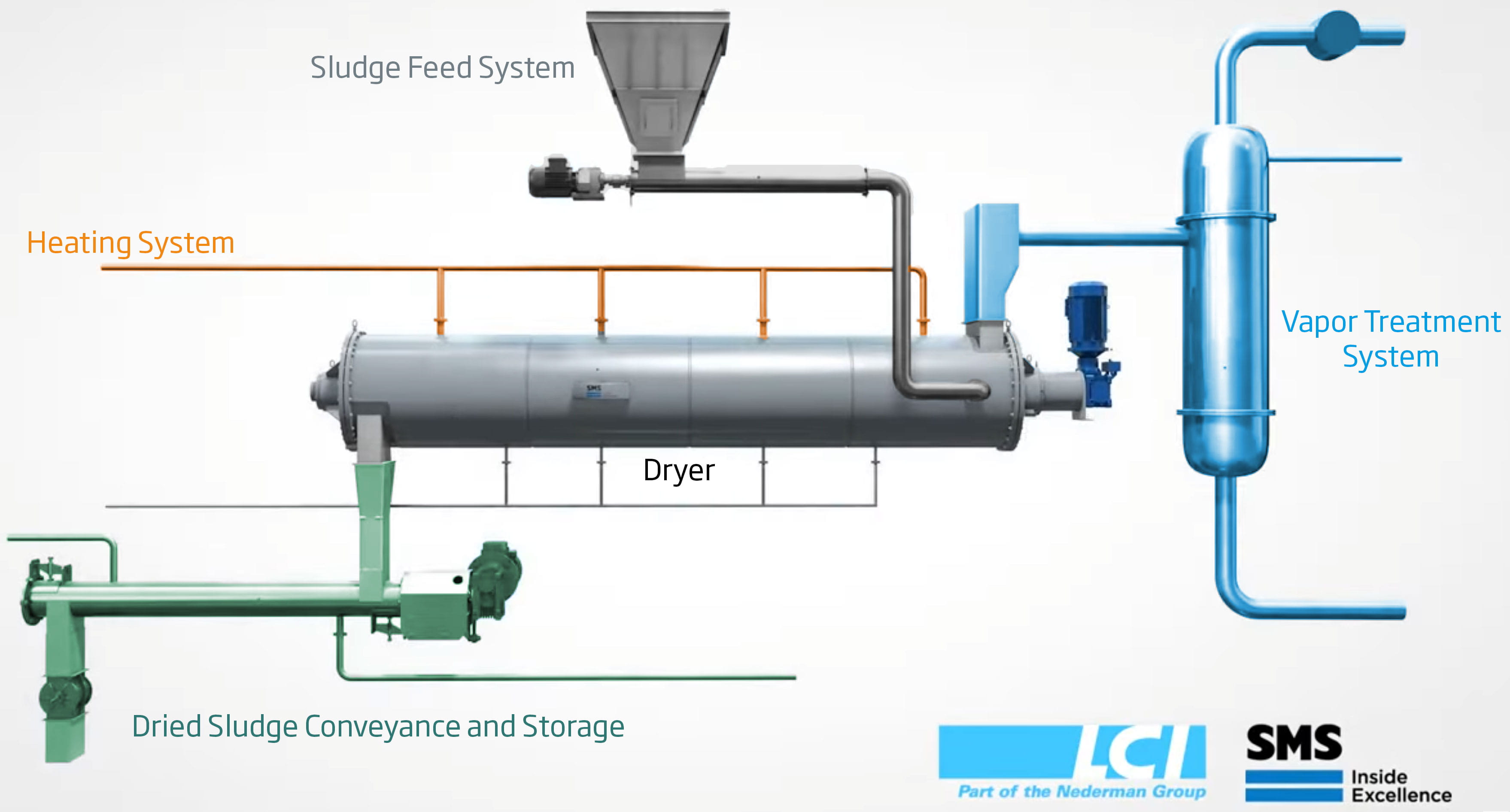

Thermal dryers become a more frequent solution as increasing regulations limit disposal options for sewage sludge. They offer disposal alternatives, such as Class A Biosolids, volume reduction, & preconditioning for thermal destruction.

4/2/2024

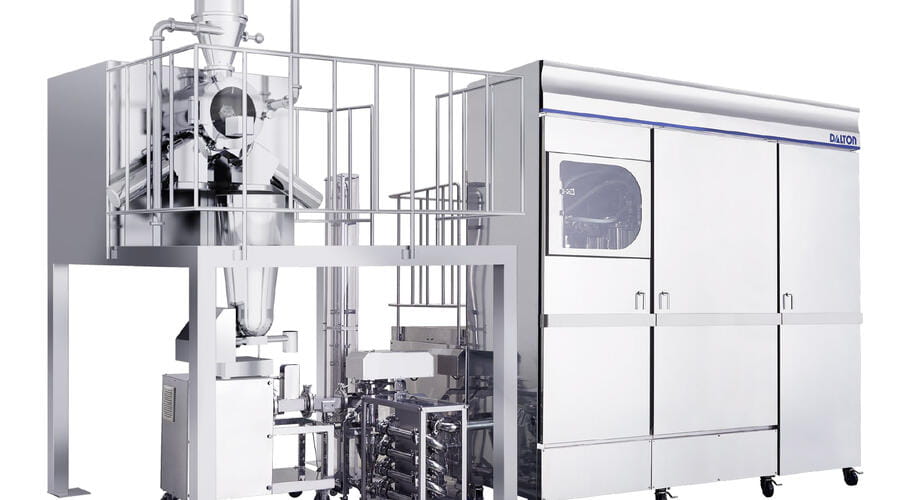

Extrusion spheronization is a manufacturing technique that has been widely used in a variety of industries. LCI has been providing extrusion and spheronization systems for over 40 years. Excellent control and process repeatability make this process well suited for manufacturing consistent and quality pellets.

2/22/2024

As the world population grows, there is an increased need for dried soy lecithin to support the food industries that serve the world's population. TFEs effectively dry the lecithin to < 1 wt% moisture, and keeps color properties, while adeptly overcoming viscosity increases created by the drying process.

2/5/2024

When considering a sewage sludge drying application, most of the focus is on the design, operation, and maintenance of the dryer itself. In reality, sludge drying is a complex process that involves many sub-processes and ancillary components. If any of these systems or processes fail or operate incorrectly, the entire drying system will be affected and may fail.

1/17/2024

Historically, solid waste landfills have been the preferred method of waste disposal due to their hands off approach, simplicity, low cost & acceptance of a variety of wastes.

6/15/2022

Paddle Sludge Dryers (also referred to as Screw Dryers) and Thin Film Sludge Dryers have both successfully dried municipal wastewater sewage sludge for many years. These dryers operate on a similar drying principle but have a different method of operation. Learn about the advantages and disadvantages of each and which is best for your application.

12/3/2020

In partnership with the Duquesne University School of Pharmacy, we are pleased to share with you this poster reprint from AAPS 2020. The poster is an exploration of the effects of various process parameters on the particle size distribution that is achieved by granulating with The Dome-Ex System.

8/25/2020

LCI has partnered with Bora Pharmaceuticals to bring you this free white paper on the advantages of extrusion spheronization (ES) as a solution for delivery challenges in controlled release dose forms.

7/28/2020

As today’s residual chemical requirements in consumer goods become more stringent, an emphasis has been put on cleaning up and “polishing” the processes used to produce these products. In order to reach these goals effectively, an evaporation process may require the use of additional stages and equipment, increasing both capital cost and space requirements.

4/8/2020

Traditionally it has been difficult to reliably and accurately spheronize material. Fortunately, exceptional Japanese engineering and manufacturing from Fuji Paudal have created a reliable and cost-effective method for the spheronization of today’s high-performance products.

4/5/2020

How to determine which evaporator design to select based on product characteristics and process requirements.