- Home

- Parts and Services

Extruder Spheronizer Mixer Parts Service

Extruder / Spheronizer / Mixer Parts & Service

LCI Corporation provides repair and refurbishing services for its extensive line of mixers, extruders, and spheronizers. These services are available for laboratory equipment as well as production equipment.

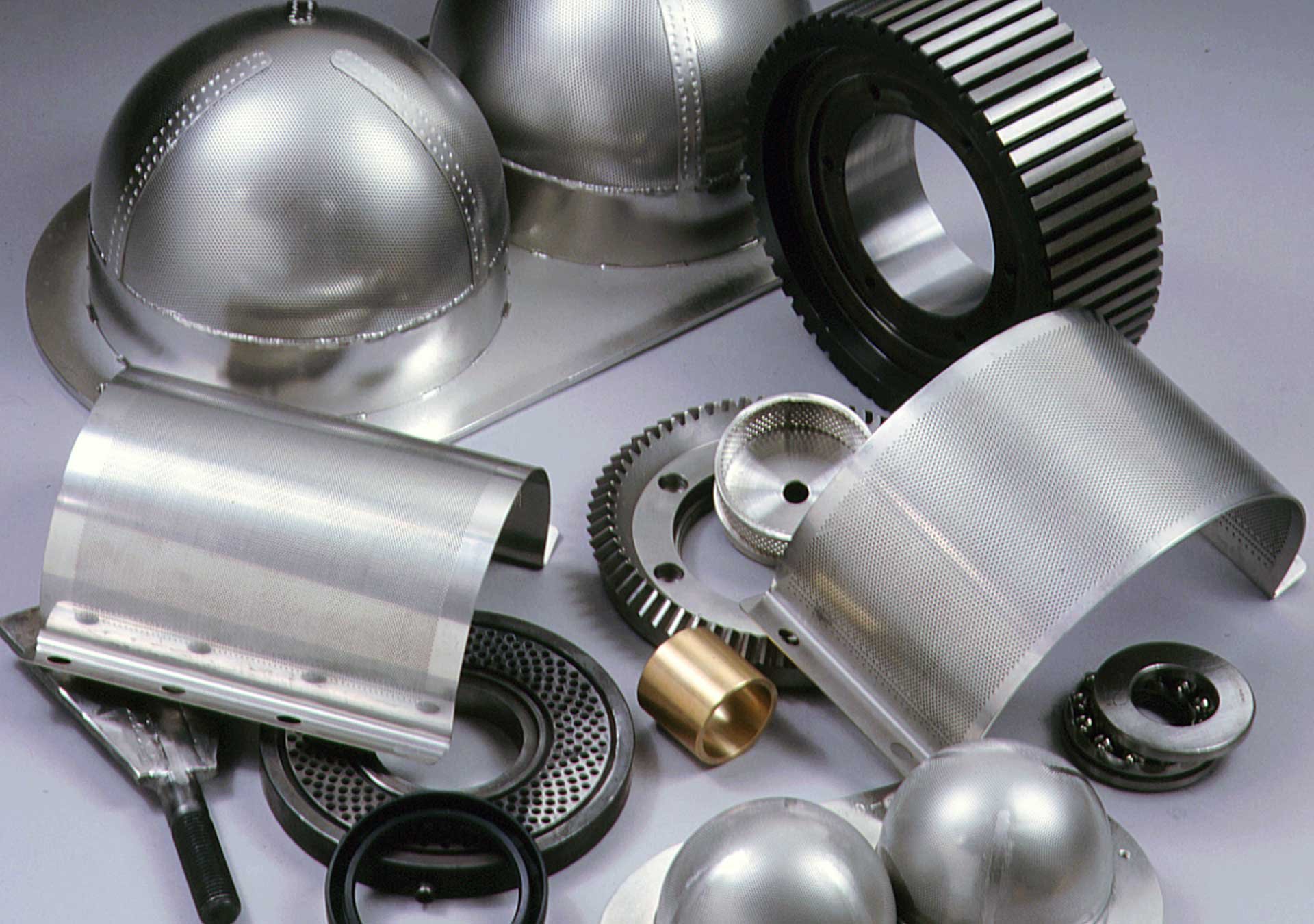

In some cases, it can be more time efficient and cost effective to repair parts of a mixer, extruder, or spheronizer. The part(s) in need of repair can be sent to LCI for evaluation. Based on our extensive experience with pug mixers, kneaders, extruders and spheronizers, LCI can rebuild major or critical components, such as kneader shafts, extrusion blades, extrusion screws, extrusion cases, spheronizer bowls, etc., and restore them to original design specifications.

LCI services our customers with around-the-clock parts support. We can provide standard wear items for LCI's (formerly Luwa) Fuji Paudal Mixers, Extruders, and Spheronizers (Marumerizers):

Extruders

- TDG-80 Twin Dome Granulator™

- TDG-110 Twin Dome Granulator™

- TDG-220 Twin Dome Granulator™

- EXD-60 Xtruder™

- EXD-100 Xtruder™

- EXD-130 Xtruder™

- EXD-180 Xtruder™

- BR-200 Basket Granulator™

- BR-450 Basket Granulator™

- BR-600 Basket Granulator™

Spheronizers

- QJ-400T Marumerizer®

- QJ-700T Marumerizer®

- QJ-700T Cascade Marumerizer®

- QJ-1000T Marumerizer®

- QJ-1000T Cascade Marumerizer®

Laboratory Equipment

- BR-150 Basket Granulator™

- DG-L1 Lab Dome Granulator™

- BTG Benchtop Granulator™

- MG-55 Multi-Granulator™

- QJ-230T Laboratory Marumerizer™

- KDRJ-2 Benchtop Kneader™

Kneaders

- KDH Series

- CKD Series

Pug Mixers

- CPM Series

Disc Pelleters

- PV-5

- PV-20

- PV-60

Extrusion Blade Expertise

When it comes to extruders, the most important and difficult components to refurbish are the extrusion blades or flights. These components are machined to close tolerances in order to maintain the necessary extrusion gap that is critical in low pressure, wet extrusion. A large extrusion gap can result in product degradation, low throughput, and possible heat generation. LCI can determine if the extrusion blades are in need of repair or replacement.

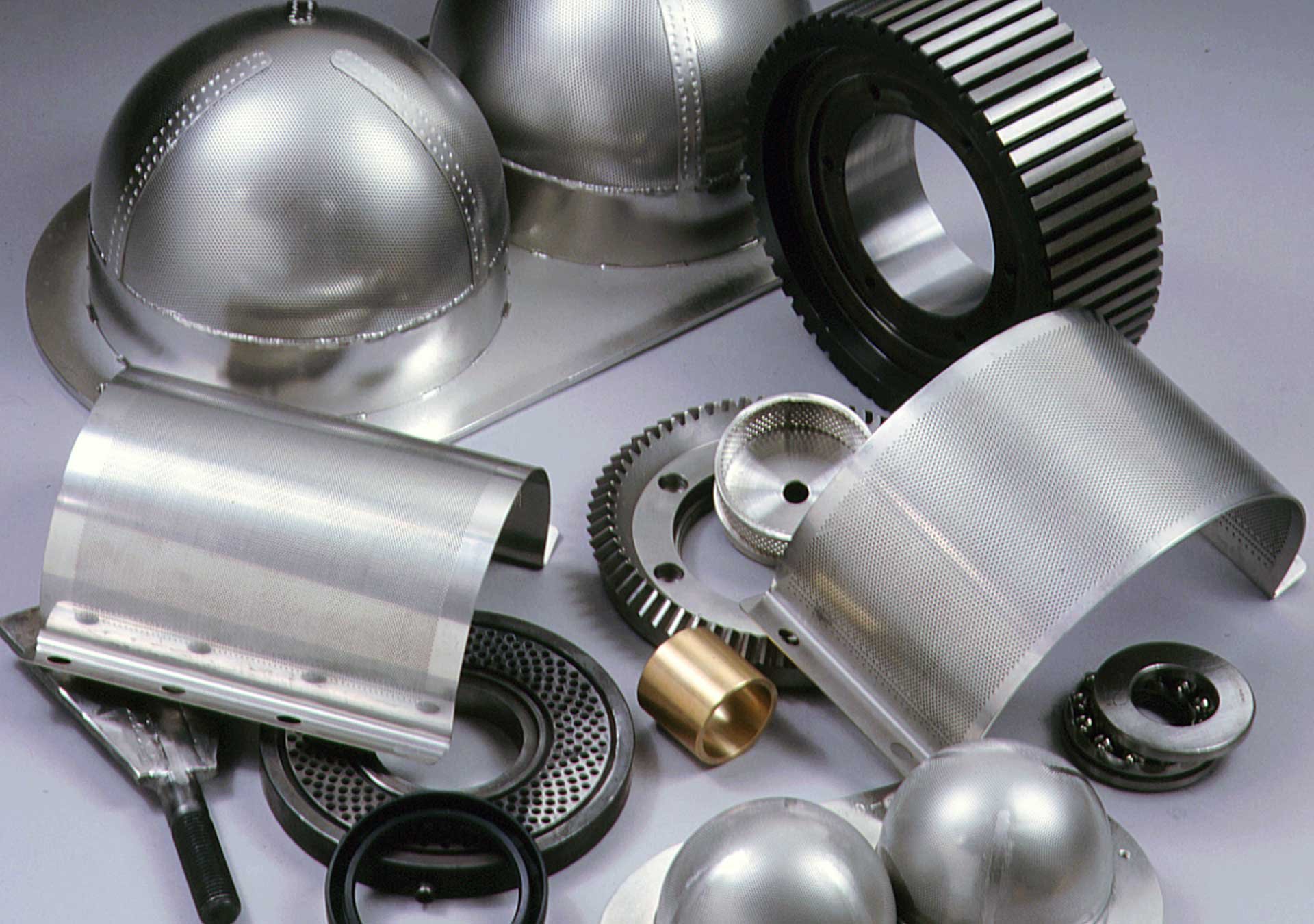

Complete Machine Refurbishing

In certain industries, years of operation with abrasive products coupled with the surrounding process environments result in significant internal and external machine wear. As part of its commitment to service, LCI offers complete refurbishing services. This service could include critical component replacement, shaft rotation, new bearings, seals, gaskets, fluid change, frame sandblasting and repainting.

LCI will perform an extensive inspection of the machine and provide a firm price, with a description of all work and parts, prior to beginning restoration services. Having a machine restored to factory specifications can result in increased capacity, lower maintenance, and lower energy costs.