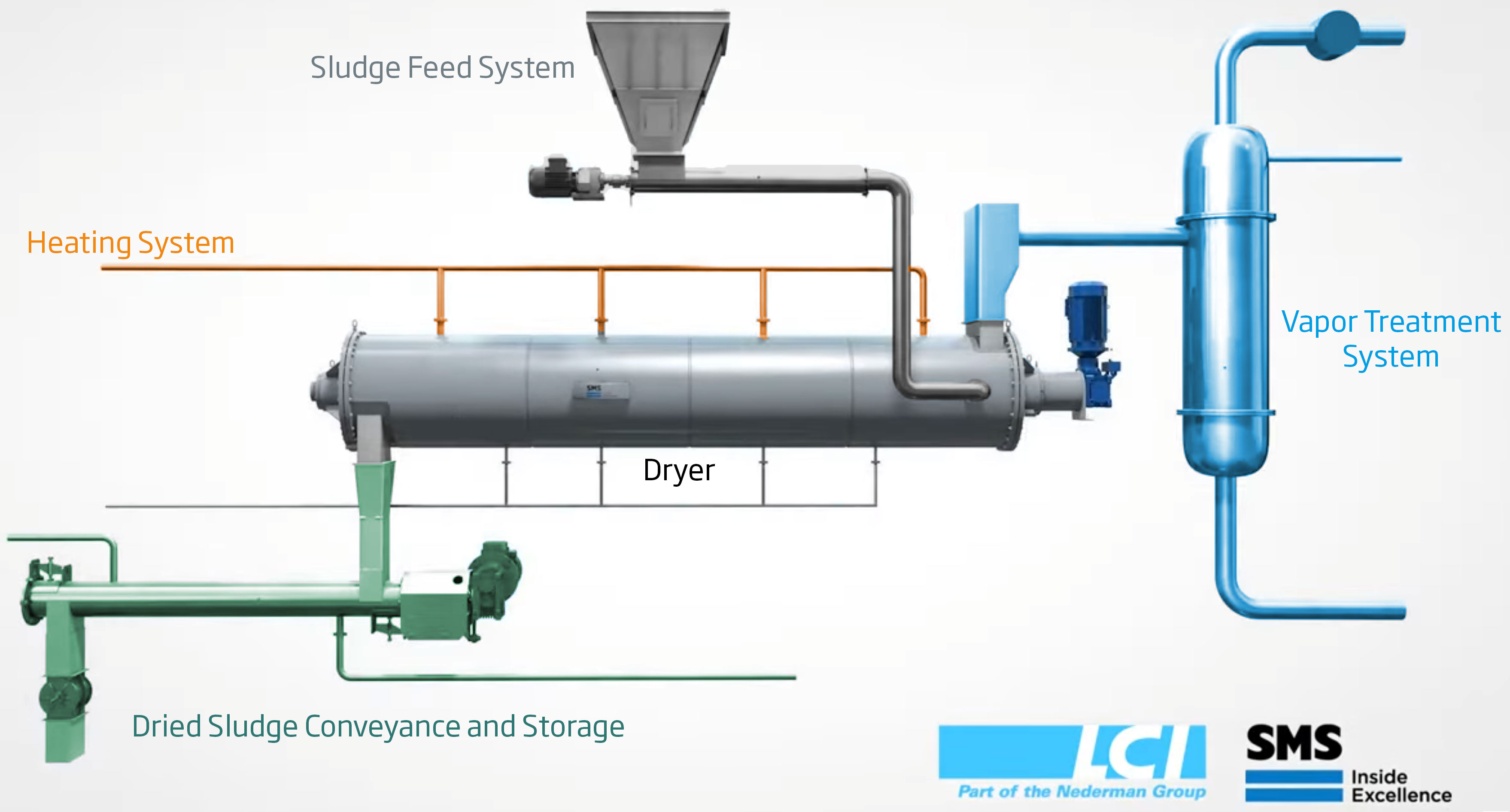

Design Considerations for Dryer Ancillary Equipment

When considering a sewage sludge drying application, most of the focus is on the design, operation, and maintenance of the dryer itself. In reality, sludge drying is a complex process that involves many sub-processes and ancillary components. If any of these systems or processes fail or operate incorrectly, the entire drying system will be affected and may fail.

When considering a sewage sludge drying application, most of the focus is on the design, operation, and maintenance of the dryer itself. In reality, sludge drying is a complex process that involves many sub-processes and ancillary components. If any of these systems or processes fail or operate incorrectly, the entire drying system will be affected and may fail.

Additionally, these ancillary systems can be quite costly, require a large space, and be challenging to operate and maintain. Also, the cost, size, and operational requirements of these components vary depending on the type of dryer. Therefore, careful consideration of these components during the project's selection and design phases is essential to create a robust, seamless, efficient, and easy-to-maintain drying system. This article will investigate the major subsystems of a sludge dryer including:

- Sludge Feed System

- Dried Sludge Conveyance and Storage Systems

- Vapor Treatment System

- Heating System

Regarding design considerations and comparisons of different designs.

Note, LCI has provided high-level information on various ancillary equipment for reference. For specific designs and specifications, it is recommended to consult the manufacturers of the specific component.

Sludge Feed System

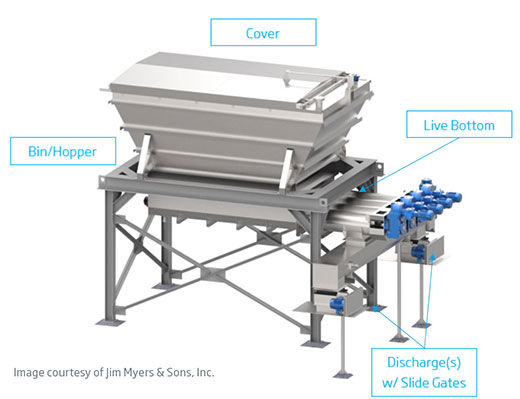

Cake Storage Hopper/Bin

The first item to the sludge feed system of a dryer is the cake hopper, also known as a cake bin, which decouples or buffers dewatering capacity from drying capacity. These hoppers are custom in design, tailored to each application. Therefore, it is important to consider many items in the design of this equipment including:

- Size and Capacity

- Required storage volume between dewatering and drying

- Use of a leveling screw or multiple drops to increase the usable capacity

- Understanding that storage volume has a significant impact on cost and footprint

- Location

- Recommended to be close to the dryer as possible, limiting pumping distances

- Climates with consistent freezing temperatures should have the hopper indoors, increasing the building size and cost

- Warm Climates can place hoppers outside, reducing building size

- Flow

- Delivery method to the hopper

- Trucks or loaders require a bin which can be dumped into

- Conveyors or cake pumps must consider routing and if multiple drops to the hopper are required

- Direct feed from dewatering equipment located above the hopper must consider the height available and size restrictions on the hopper

- Hopper geometry must consider the bridging of material inside the hopper

- Discharge design to feed pump(s)

- Feed pump(s) can be located under or to the side the hopper

- Recommend installing a gate valve isolating the pump and hopper for servicing

- Allowance for duty/standby pumps if required

- Allowance for material bypass for emergency situations

- Level measurement

- Ensures the hopper is not empty or overfilled, examples include:

- Lazer

- Ultrasonic

- Load Cells

- The system may need to be designed for combustible gases.

- Due to prohibitive cost, minimal maintenance, and high reliability, typically, redundant hoppers are not required

Cake Pump

While a few dryers use a conveyor for feeding, most dryers utilize progressive cavity pumps due to their smooth and consistent flow, as well as the ability to achieve high pumping pressures. Double piston pumps can also be considered but are more complex and have a higher initial capital cost. When designing a pumping system, some of the important items to consider are:

- Piping design between the pump and dryer to minimize pressure loss:

- Limiting the piping distance and vertical rise

- Minimize number of bends, tees, and valves

- Use full port components, long radius bends, and large diameter piping

- Calculate the additional pressure loss of a specific dryer’s feed system

- Have an expert confirm the piping design and anticipated pressure losses

- Design for excess pressure and flow capacity

- Dry run and pressure protection for the pump

- Maintenance

- Grit, trash, and high pump pressures create higher wear

- Design the layout for ease of maintenance

- Consider redundant pumps especially in high operational hour applications due to pump maintenance requirements

The cake storage and pumping systems are critical to the operation of the dryer system. If these systems are not designed properly, sludge cannot be pumped into the dryer limiting or completely stopping the operation.

Dried Sludge Conveyance and Storage System

Cooling Conveyor

After the sludge is dried, it should be cooled to below 120°F (50°C) to avoid the risk of fire and explosion during storage. If a temperature below 120°F (50°C) cannot be achieved naturally, a cooling conveyor should be employed, using a water-cooled jacket and auger to remove heat from the dried sludge. Among the items to be considered in design are:

- Cooling Water free from contaminants which foul the heat exchange surface

- Design Considerations

- Configured to operate with the warmest cooling water supply temperature

- Integration of the cooling conveyor as part of the dried sludge conveyance system reducing the length and cost of the additional conveyance system

- Temperature Measurement to control the system including optimizing water uses and ensuring the material is cooled properly

- Maintenance Considerations

- Cleaning of the heat exchange surface may be required from time to time

- Typically, redundant cooling conveyor systems are not considered due to infrequent maintenance requirements, complexity, and cost

Rotary Valve

Dryers operate under negative pressure to contain vapor, dust, and odor therefore draw air into the dryer, reducing efficiency, increasing vapor volume, and elevating risk of fire and explosion. Rotary valves (also known as an airlock) are used to minimize leakage air into the dryer. While not all dryer designs include rotary valves, designs which do are more efficient, require less vapor volume to treat and are safer. A few considerations for rotary valve design include:

- Design

- Design with at least two sealing strips in contact with the frame creating a tight seal

- Self-cleaning design to eliminate clogging

- Proximity switches to ensure the valve’s rotation avoiding system blockages

- Parts in contact with the sludge should be designed for corrosion resistance

- Proper rating for fire and explosion hazards

- Maintenance

- Area around the valve for servicing and cleaning

- Replacement of sealing strips to maintain a tight seal

- Possible high wear on parts in contact with abrasive materials requiring replacement

- Most wear occurs over time and can be avoided with preventative maintenance so typically redundant rotary valves are not considered.

Dried Sludge Conveyors

Once the sludge has been dried and cooled, it is transported for storage. Many factors should be considered when designing a dried sludge conveyance system, such as:

- Conveyance distance and direction

- Integration with storage systems, such as silos or requirements for multiple drop points

- Sizing with excess capacity

- Consideration of points where bridging of material may occur

- Maintenance requirements

- Explosive dust hazards

- Cost

Typically, the following conveyors have been used to transport dried sludge:

- Screw Conveyors

- Tubular Drag (Drag Chain) Conveyors

- Bucket Conveyors

- Combination of these conveyors

Each conveyor design has its advantages and disadvantages which are listed in the table below:

| Screw Conveyor | Tubular Drag | Chain & Bucket | |

|---|---|---|---|

| Conveyance Planes | 2D | 3D | 2D |

| Maximum Vertical | 45° | 90° | 90° |

| Length | Short | Long | Short |

| Tight Footprint | No | Yes | Yes |

| Compatibility w/ Silos | No | Yes | Yes |

| Dust Buildup | Low | Low | High |

| Robust | High | Medium | Medium |

| Maintenance | Low | Medium | High |

Normally due to size, layout and cost, redundant conveying systems are difficult to employ. Therefore, care should be taken to complete preventive maintenance and understand the maintenance requirements of each design.

Finally, as each application has different requirements, there is not a one-size-fits-all conveyor system. Therefore, each conveyance system should be carefully considered during the design process.

Dried Sludge Storage

Dried sludge must be conveyed to storage after drying, so it is important to consider the type of storage system for each drying application. Typical storage systems include:

- Silos

- Holding Areas

- Truck Loadout

- Super Sacks

When selecting the correct storage system, some of the items to consider are:

- Available Footprint and Height

- Available Equipment (Trucks or Loaders for Example)

- Disposal/Hauling Method

- Complexity

- Maintenance and Operator Requirements

- Dust Dispersion and Hazard Considerations

- Cost

Each type of storage has its advantages and disadvantages which are listed in the table below:

| Silo | Holding Area | Truck | Super Sacks | |

|---|---|---|---|---|

| Cost | High | Low | Medium | Low |

| Complexity | High | Low | Medium | Medium |

| Volume | Large | Large | Medium | Small |

| Horizontal Footprint | Low | High | Medium | Medium |

| Product Handling | Low | High | Medium | Medium |

| Cross Contamination | Low | High | Medium | Low |

| Maintenance | High | Low | Low | Medium |

| Dust Dispersion | Low | High | Medium | Low |

| Nitrogen System | Yes | No | No | No |

| Designed for Explosive Dust | Yes | No | No | No |

Typically, due to size, maintenance requirements, and/or cost redundant storage systems are not implemented.

Dried sludge conveyance and storage systems are highly configurable and should be carefully considered for each individual application.

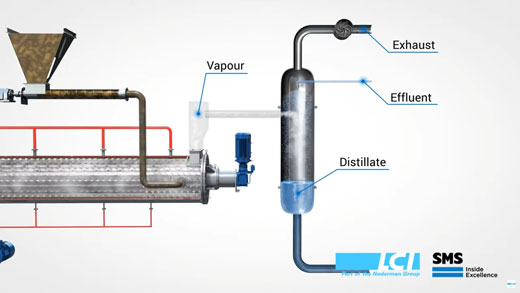

Vapor Treatment System

Condensation System

The drying process creates a substantial amount of vapor which must be treated. Typically, the vapor first flows to a condenser system, which is designed to cool the vapor stream, condensing the evaporated water to be sent for treatment. Various types of condensers are used in drying applications, and the choice of condenser type is influenced by the type of dryer being operated. Direct dryers, which use high volumes of air, typically utilize packed media condensers, crossflow condensers, or rely on heat recovery only with no separate condenser. Indirect dryers, with low volumetric vapor flows, typically employ barometric or shell and tube condensers. Below is a chart comparing the different condensing technologies:

| Barometric | Shell & Tube | Packed Media | Cross Flow | No Condenser / Heat Recovery Only (HR) | |

|---|---|---|---|---|---|

| Dryer Type | Indirect | Indirect | Direct | Direct | Direct |

| Condensing Type | Direct | Indirect | Direct | Indirect | None |

| Heat Recovery | Secondary Plate & Frame | Integrated | Secondary Plate & Frame | Cross Flow | Cross Flow |

| Complexity | Low | Medium | High | High | Medium (HR) |

| Fouling | No | Yes | Yes | Yes | Yes (HR) |

| Maintenance | Low | Medium | High | High | Medium (HR) |

| Wastewater Volume | High | Low | High | Low | Low (HR) |

| Emissions Treatment System | Small | Small | Medium | Medium | Large (HR) |

Most applications do not consider completely redundant condenser systems due to size and cost constraints. However, it is important to consider the maintenance of each type of condenser system. For example, for a plate and frame heat exchanger, which requires frequent cleaning, a standby unit may be required while the other heat exchanger is cleaned. Also, with packed media condensers, a second set of packing might be advantageous to pull the other set of packing for cleaning.

The operation of the condensing system is often overlooked when selecting a dryer. However, condensing systems are quite different from one another, and the condenser design affects other processes such as emissions control, cooling water volumes, and wastewater volumes.

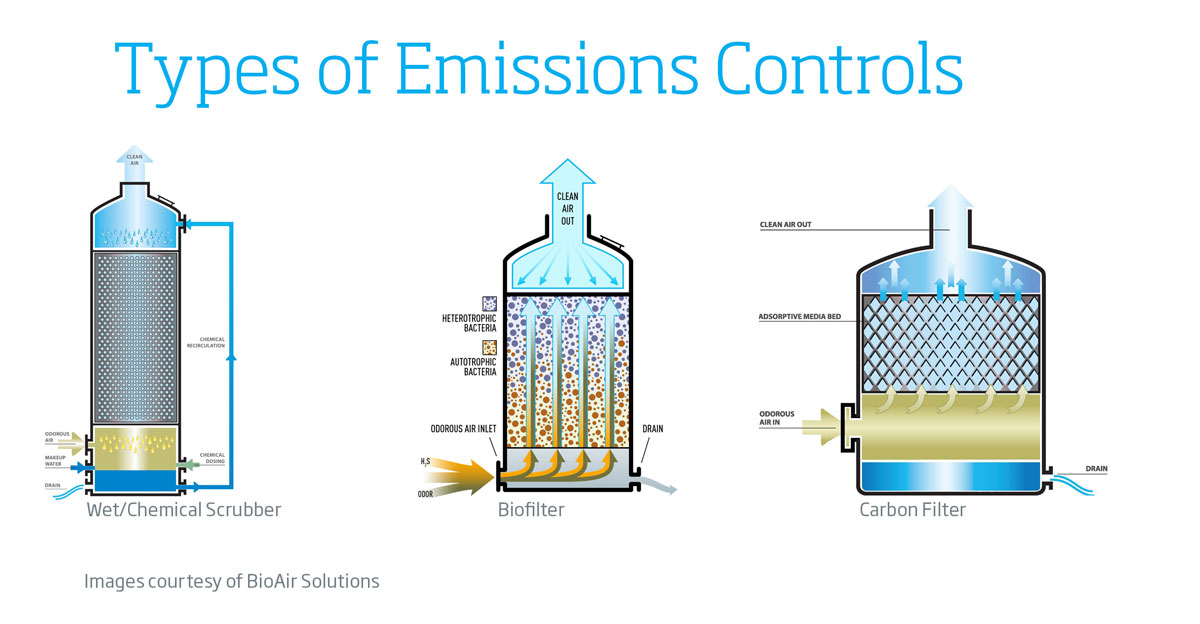

Emissions (Odor) Control

The exhaust vapor from the condenser system typically requires treatment for odors and pollutants, based on local regulations and the contaminants in the vapor stream. Historically, four types of emissions control systems have been used:

- Wet Scrubbers

- Biological filters

- Carbon filters

- Thermal oxidizers.

There are many factors which go into the selection of the emission control system, some of which include:

- Volume of vapor to treat

- Type and concentration of contaminants

- Local regulations

- Operation and Maintenance Requirements

- Equipment Size

- Cost

First, the selected equipment must be able to treat the vapor generated by the drying application. Below is a comparison of the treatment capabilities of the different emissions control systems:

| Wet / Chemical Scrubber | Biological Filter | Carbon Filter | Thermal Oxidizer | |

|---|---|---|---|---|

| H2S Removal | Yes | Yes | Yes | Yes |

| NH3 Removal | Yes | Yes | No | Yes |

| PFAS Destruction | No | No | No | Yes |

| High Concentrations | Yes | No | No | Yes |

| Variable Concentrations | Yes | No | Yes | Yes |

| Particulate Matter | Yes | No | No | Yes |

| High Humidity | Yes | Yes | No | Yes |

Additionally, each emissions control equipment has advantages and disadvantages which must be considered. Below is a chart comparing the different treatment technologies:

| Wet / Chemical Scrubber | Biological Filter | Carbon Filter | Thermal Oxidizer | |

|---|---|---|---|---|

| Simplicity | Medium | High | High | Low |

| Maintenance | Medium | Low | Medium | High |

| Water | Yes | Yes | No | No |

| Wastewater | Yes | Yes | No | No |

| Thermal Energy | No | No | No | Yes |

| Media Exchange | Rare | Rare | Often | Never |

| Cleaning Required | Yes | Yes | No | No |

| Chemicals Required | Yes | No | No | No |

Due to size and cost, typically, redundant emissions systems are not considered. However, it is important to understand emissions equipment can be complex, so it is important to select a robust system, have recommended spares available and complete preventative maintenance.

The Vapor Treatment System affects many aspects of the drying system including cooling water requirements, wastewater flows, chemical consumption and even air permitting. It is important to consider the vapor system of each dryer as a part of selection criteria to insure the best drying system is chosen for the application.

Heating Systems

All thermal dryers require heat, and each dryer requires specific a type or types of heating media. Historically, four types of heating media have been used:

- Air

- Water

- Steam

- Thermal Oil

Air systems are heated by a furnace and air directly fed into the dryer, meaning the combustion air enters the drying area. Water, thermal oil, and steam systems indirectly apply heat either to the drying air through a heat exchanger or directly to the sludge through a heated surface. As different dryers are designed with a specific type or types of heating medium, it is important to understand the advantages and disadvantages of each medium to help select the best dryer for each drying application.

Below are charts of the different heating mediums and their advantages and disadvantages:

| Air | Water | Steam | Thermal Oil | |

|---|---|---|---|---|

| Type | Direct | Indirect | Indirect | Indirect |

| Efficiency | High | Medium | Medium | High |

| Exhaust Air for Treatment | High | Low | Low | Low |

| Flashing | No | Yes | Yes | No |

| High Pressures | No | Yes | Yes | No |

| Certified Boiler Operator | No | Maybe | Yes | No |

| Duckwork / Pipework | Large | Medium | Small | Medium |

| Duckwork / Pipework Complexity | Low | Medium | High | Low |

| Maintenance | Low | Medium | Large | Medium |

| Flammable | Yes | No | No | Yes |

| Cost of Media | Low | Low | Low | High |

| Corrosive | Yes | Yes | Yes | No |

| Blowdown | No | No | Yes | No |

| Corrosion Inhibitors | No | Yes | Yes | No |

| Pumping System | Yes | Yes | No | Yes |

| Heat Transfer Area | Large | Medium | Small | Medium |

Heating Systems are one of the more complex aspects of drying requiring a lot of attention and maintenance. Typically, they require a once yearly inspection, but normally redundant systems are not used due to cost and complexity. Again, it is important to complete all preventative maintenance of heating systems to avoid a dryer system shutdown.

Finally, it is important to understand the design and operational requirements of the required heating system to ensure the best dryer system is chosen for a specific application.

Ancillary equipment is an important consideration when selecting and designing a drying system. These systems have a huge effect on cost, operation, maintenance, and system performance. Considering the type of systems each dryer requires and understanding the performance of the complete dryer system is paramount to a successful dryer operation.

If you have questions about drying or dryer ancillary equipment, please contact LCI Corporation, and we would be happy to help.