Spheronization - How to make Spherical Pellets

Traditionally it has been difficult to reliably and accurately spheronize material. Fortunately, exceptional Japanese engineering and manufacturing from Fuji Paudal have created a reliable and cost-effective method for the spheronization of today’s high-performance products.

How It Works

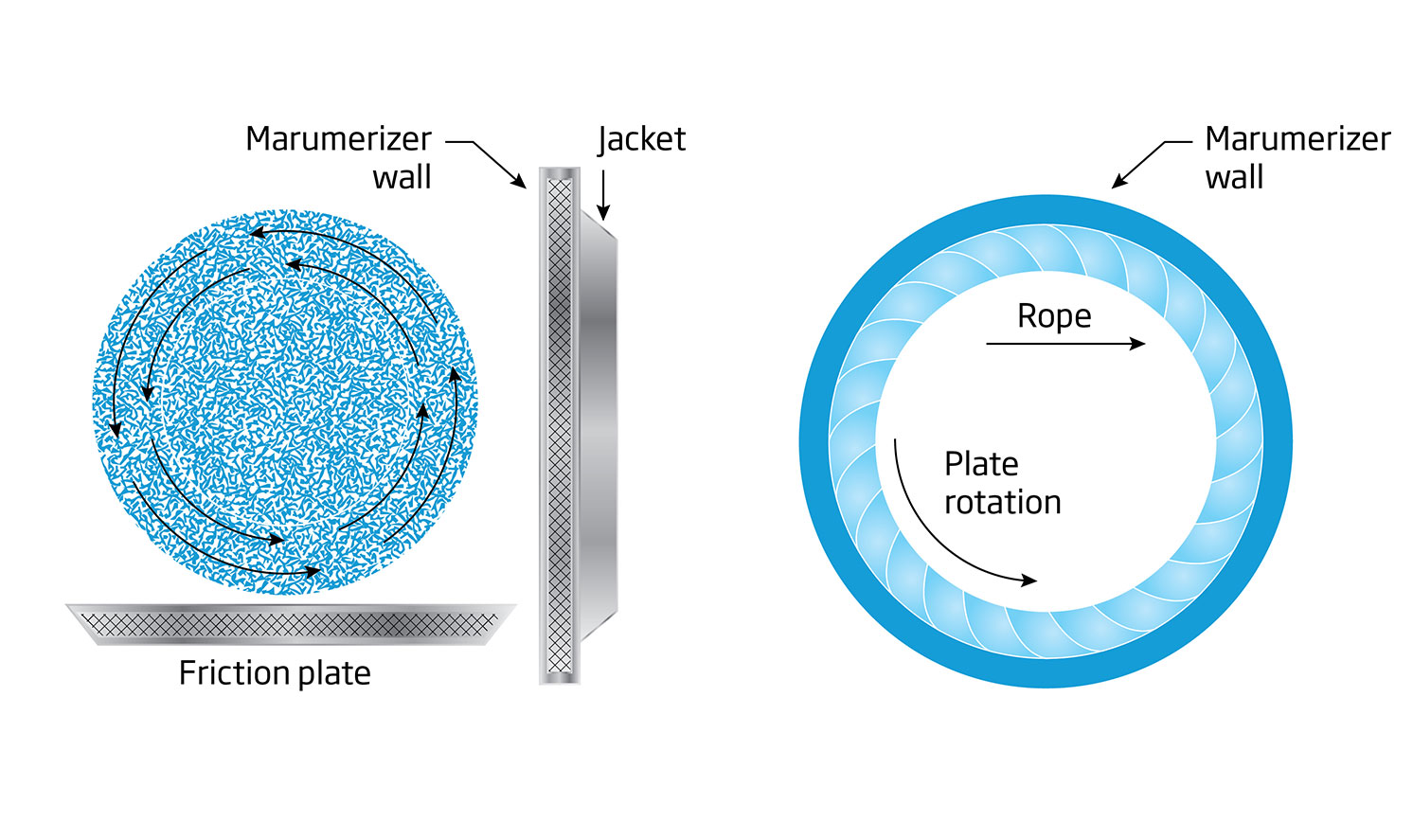

The Marumerizer spheronizer is comprised of three main components: a vertical cylinder with discharge port, a circular "friction" plate and a variable speed drive train which turns the plate.

The feed material to the spheronizer can be extruded particles or moist granules from a mixer / granulator. Since an extruded particle has at least two dimensions already defined, a narrow final particle size distribution is possible.

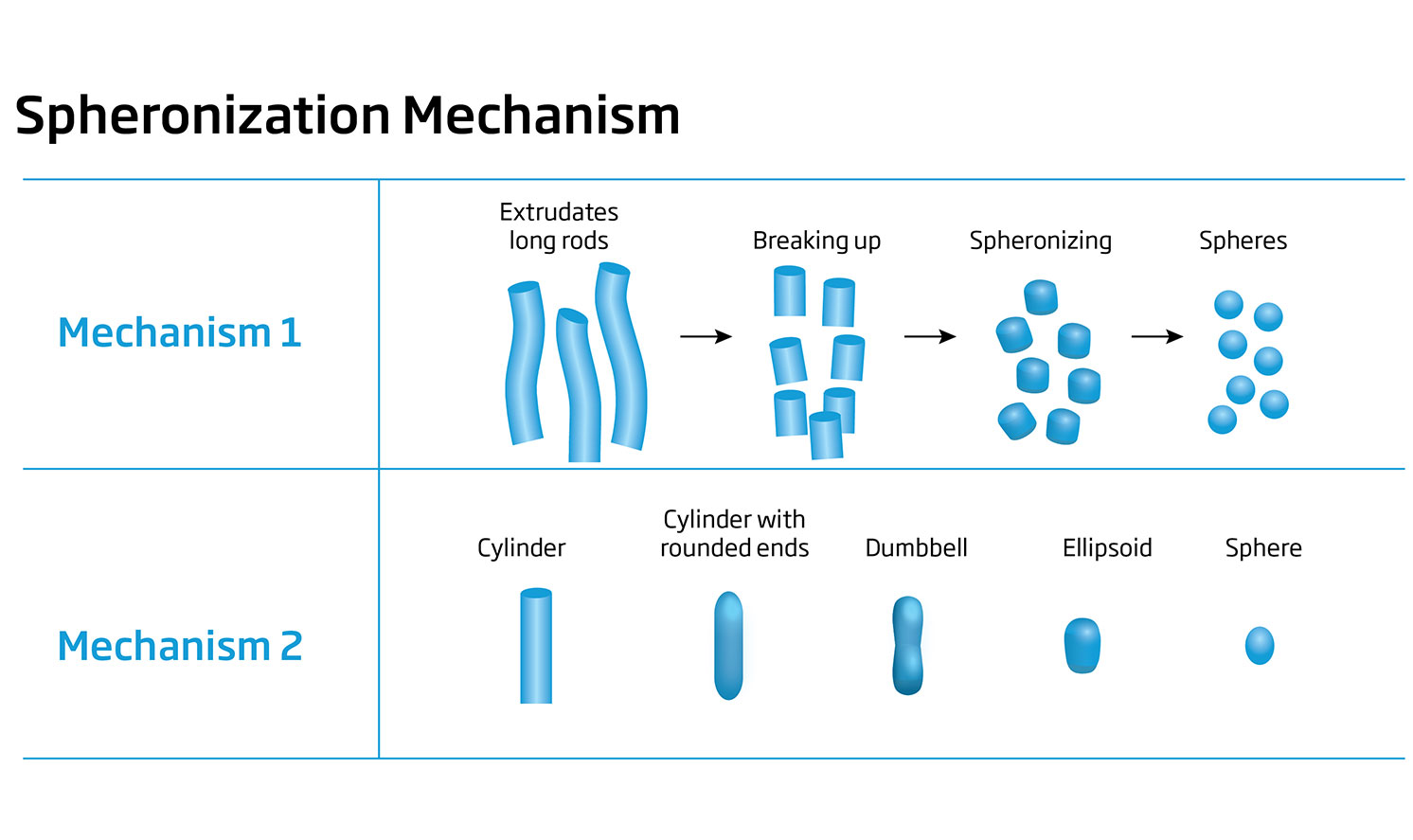

Particles are fed onto the spinning friction plate, which throws them against the inside wall of the cylinder. Extruded particles are quickly broken into segments approximately one diameter long. Centrifugal and gravitational forces create a mechanically fluidized ring of particles. Collisions with the wall, friction plate and other particles result in the plastic deformation of each granule, quickly creating a spherical shape. The desired shape for a specific application is time and formulation dependent and is achieved, predictably and repeatedly, in a brief period called the "spheronization time".

Features and Benefits

Spheronization improves your product's performance by:

- Producing a smooth particle surface suitable for thin layer coating

- Forming granules with a specific bio-consumable shape

- Conditioning particles to prevent generation of dust and fines from usage or shipping

- Increasing flowability by elimination of sticking or bridging points

- Increasing the apparent bulk density up to 25% compared to extruded material

Spheronization Applications

Pharmaceutical

- Controlled release pellets

- Multi particulate systems

- Sustained release polymer coated pellets

- Enteric coated pellets

Agricultural Chemical

- Herbicides

- Insecticides

- Fungicides

Chemical

- Catalysts

Food Products

- Flavors

- Nutraceuticals

Making the Spherical Pellets

Get Started on solving your application today! We will help you every step of the way.

Are you looking to improve your process with spheronization? LCI has the technology and the process expertise to help you every step of the way. Click here to chat with one our process experts and we can help you solve your application problems right away. Or you can send us an email with your needs and we will provide you with an answer shortly.