Frequently Asked Questions About Sludge Dryers

What Dryness Level Can be achieved with a Thin Film Sludge Dryer?

The Thin Film Dryer is flexible with the end product dryness it produces. Product can be partially or fully dried between 30-95% DS for use in fluidized bed incineration, incineration, composting, landfilling, gasification, pyrolysis, agricultural use or more.

The dried sludge can meet Class A biosolids defined by 40 CFR Part 503 for pathogen reduction by:

- Alternative 1 - Time and Temperature

- Alternative 5 - Treated in a Process to Further Reduce Pathogens (PFRP). In this case the dryer meets the process of Heat Drying by indirectly drying biosolids to 10% moisture or less and heating the biosolids to greater than 80°C (176°F).

The Thin Film Dryer meets the vector attraction requirements of Part 503 requirement by:

- Option 7 – Dry biosolids with no unstabilized solids dried to at least 75% solids

- Option 8 – Dry biosolids with unstabilzied solids dried to at least 90% solids

A unique feature of the Thin Film Dryer is it can be modified to change the output dry solids (%DS) as a plants process needs change, making the most flexible dryer on the market.

What are the end product characteristics of a Thin Film Dryer?

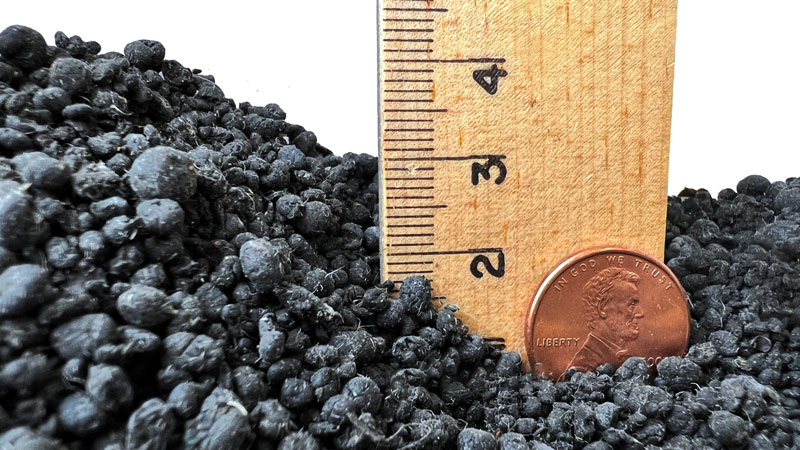

The Thin Film Dryer outputs pellet like material with a density greater than 40lb/cuft. The size of the pellets decrease as the material is dried to a higher %DS in the dryer. When combined with the optional linear dryer, the dryer system can configure the output pellet size in a low dust product.

If the dryer output is not suitable for an application, LCI’s experience in granulation can help tailor the dried sludge product to a specific size including use of pellet mills and granulation.

What are the heating requirements for a Thin Film Dryer?

The Thin Film Dryer is an indirect dryer which uses thermal oil, steam, or hot water to heat the dryer. The dryer can work with a myriad of heat sources including natural gas, digester gas, electricity, solar energy, waste heat sources and more.

Typical heat requirements are:

- Full Drying – less than 1150 BTU/lb of evaporated water (without heat recovery)

- Partial Drying – less than 1300 BTU/lb of evaporated water (without heat recovery)

Typical Limits for the heating medium are:

- Steam up to 356°F (180°C) at 145psia (10bara)

- Thermal oil up to 428°F (220°C)

- Hot water up to 140°C (284°F)

Higher temperatures are not recommended for drying due to a decrease in drying efficiency from the Leidenfrost (Film Boiling) effect.

How can the Thin Film Dryer help be sustainable and mitigate climate change?

The Thin Film Dryer heating process is designed with configurability and sustainability in mind. There are many options for the dryer to help mitigate climate change.

- The indirect drying design makes the Thin Film Dryer one of the most efficient in the market even without heat recovery. It is 10-30% more thermally efficient than other dryers on the market lowing the amount of energy and therefore, carbon released to the atmosphere.

- The dryer can recover up to 90% of its heat from the vapor stream in the form of 90°C (194°F) hot water. This waste heat can be useful to heat digesters or be used for other heat requirements like district hot water systems or preheating sludge. This further lowers the climate impact of the drying process.

Recent Developments with the Thin Film Dryer allow for even greater efficiency gains. For example,

- The dryer can operate under a vacuum drying condition lowering the evaporation temperature. This allows the dryer to operate on low pressure steam or hot water down to 90°C (194°F), use waste heat sources, and reduce thermal consumption and greenhouse gas emissions by 10%.

- Dual stage drying system in which the waste heat of one dryer is used to heat another. This can lower heat consumption by up to 45% compared to the basic dryer further reducing the carbon footprint of the dryer.

Furthermore, the basic dryer design can be reconfigured with upgraded heat recovery or vacuum drying systems in the future to reduce heat consumption and the effects of greenhouse gas emissions and carbon footprint.

Please contact LCI for additional details on these processes and how we can help create a sustainable dryer project for you.

How is safety maintained with a Thin Film Dryer?

Thin Film Dryers were developed with safety in mind.

- The dryers are indirect dryers with no combustible gases or embers from the heating system enter the drying area.

- The dryers use an inert atmosphere where oxygen levels are maintained and controlled below the levels of fire and explosion risk.

- The dryers maintain a negative internal pressure pulling all dust and hazardous drying substances to the emissions control system and out of the operational area.

- There is no contact between moving parts internal to the dryer to create a spark.

- The system is tied together by an instrumentation and control system which monitors and maintains a safe drying environment throughout the drying process.

Furthermore, LCI will work with you to develop the design based on the latest National Fire Protection (NFPA) codes and work with your Dust Hazard Analysis team to ensure the entire process is safe from fire and explosion.

What Maintenance is required of a thin film dryer?

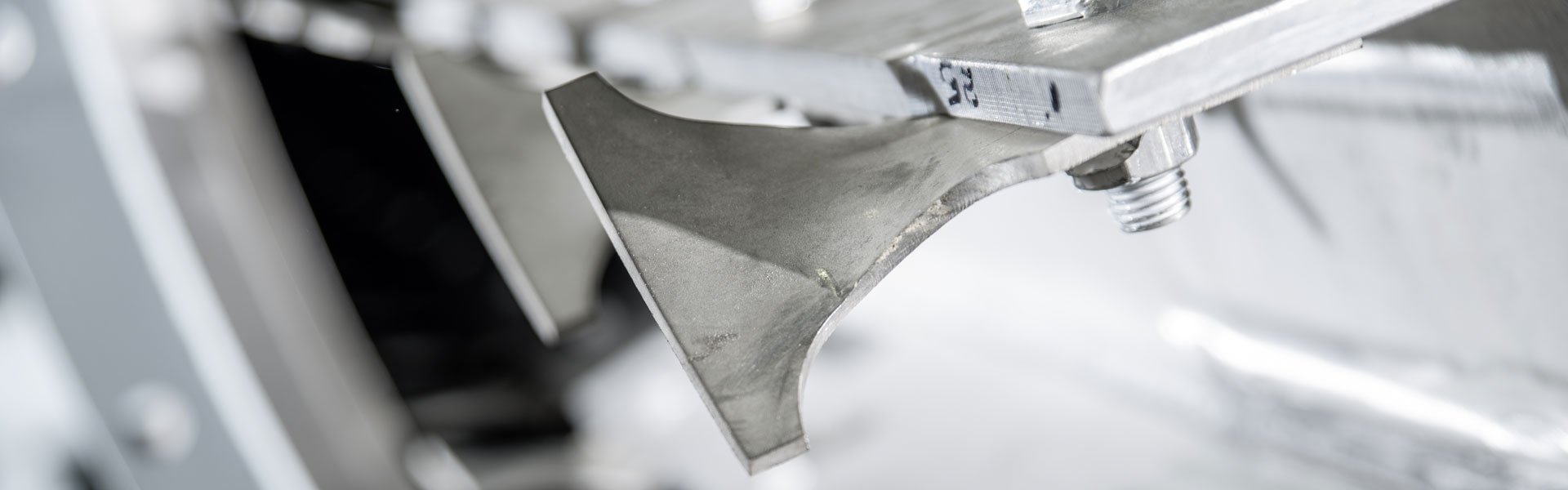

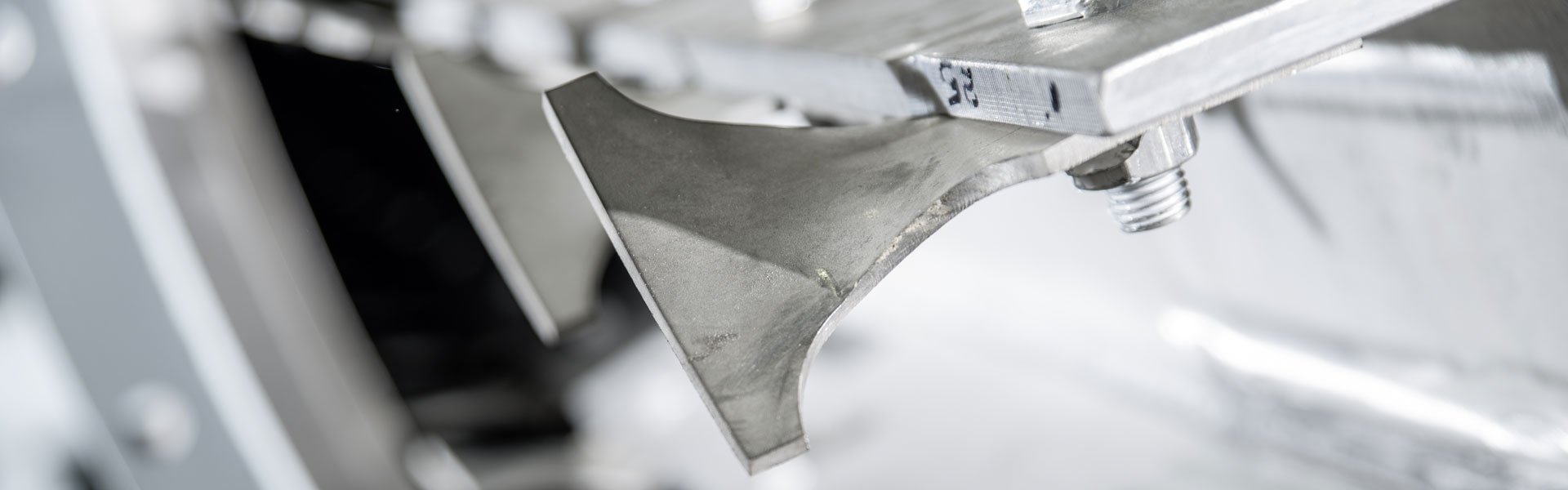

The Thin Film Dryer is simple and easy to maintain. The system has a single wear part, the blade, which is bolted to the edge of the rotor. Typically, the blades are inspected yearly using a preconfigured trolley system to pull the auger.

Blades which are worn are simply unbolted and replaced. All maintenance is performed at the floor level without heaving lifting, draining of heating fluid, and, factory synchronization or re-alignment of the equipment.

Are there any emissions requirements to consider when drying sludge?

Due to the nature of sludge, there is a risk of odor from the drying process as well as dust production. Many sludges contain sulfur-containing compounds such as Hydrogen Sulfide (H2S), Ammonia (NH3) and Volatile Organic Contaminates (VOC’s) such as amines (Guide To Field Storage of Biosolids - Chapter 2) You should consider your local air regulations when designing and sizing a dryer.

To lessen the impact of the cost of emissions control equipment, the Thin Film Dryer is designed with a small airflow (typically between 20-200 CFM) meaning there is a small volume of air to treat compared to other technologies like belt dryers and drum dryers. The first line of defense is a barometric/mixing condenser which precipitates out most of the liquid evaporated out the dryer and curb dust emissions.

Next, if required, the small air flow can be sent to a small odor control system, an existing odor control system or to the thermal heating system to be oxidized, reducing the cost of the overall system.

For more detailed information please reach out to our team to discuss your particular application requirements.

How is a Thin Film Dryer Sized and how much does it cost?

With over 100 drying applications completed, LCI and our partner SMS-BUSS-Canzler have the process knowledge to design your drying application. With the following information we can start the design process:

- The type of sludge

- The amount of sludge

- The feed solids %DS

- The required discharge solids %DS

- Any dried sludge characteristics required

- The heating medium available along with its temperature

- The yearly desired operational hours

With this information we develop design for your application by using our internally developed heat transfer coefficients based on our years of experience in evaporation and drying. Once the dryer is sized our team can put together a price estimate for the dryer.