- Home

- Powder Handling

- Mixers

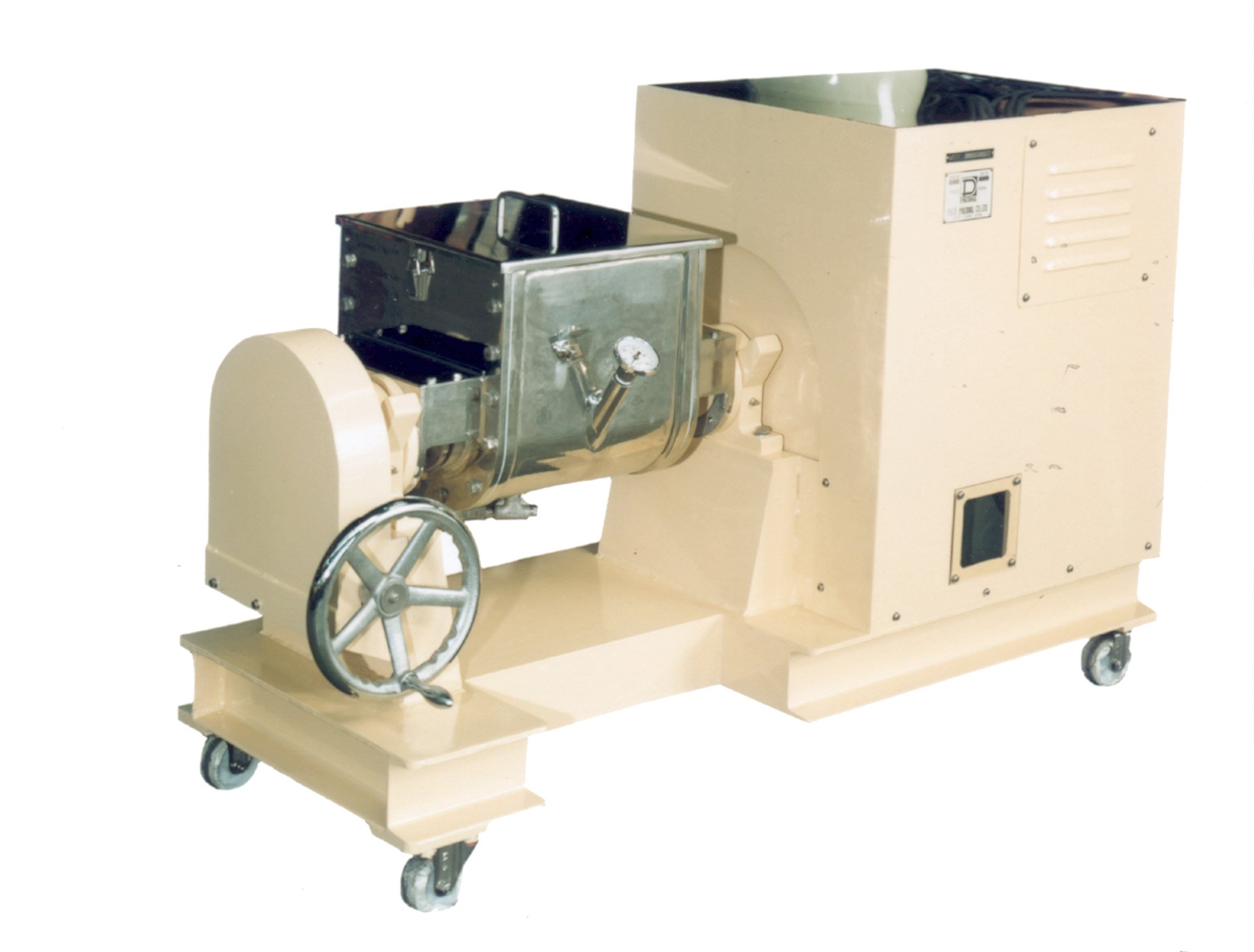

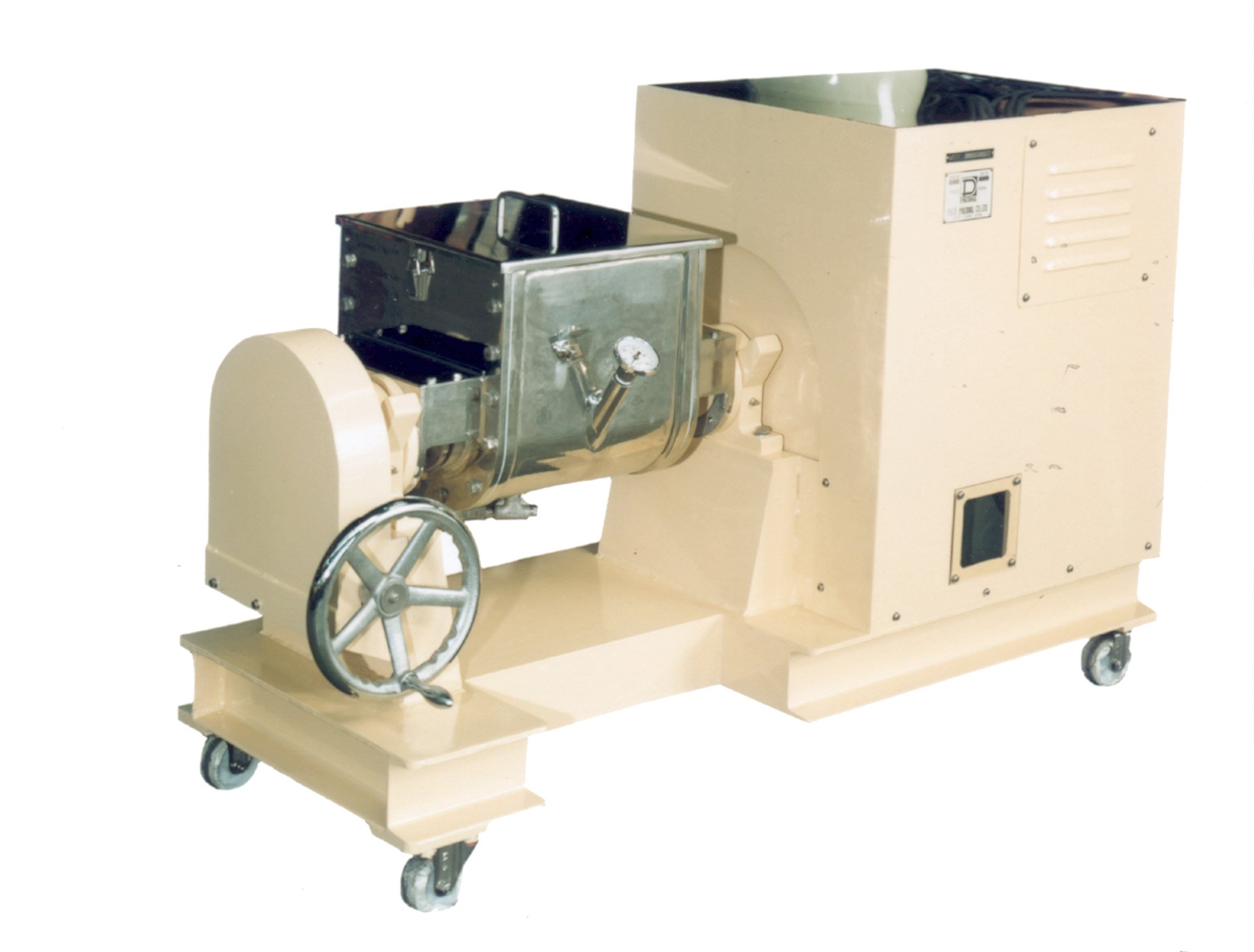

Batch Kneaders

Batch Kneaders

Batch kneaders are used for mixing powders and liquids to form a homogeneous wet mass, ideal for downstream processes requiring consistent moisture levels.

The Kneader’s rugged industrial design, coupled with the described features, make this device ideal for wet granulation processes and provide years of trouble-free operation.

Dry ingredients are manually charged into the bowl. Liquid is added to the moving dry powder and mixed by the counter rotating twin shafts, producing a uniform wet mass. Once the desired mixture characteristics are achieved, the kneader bowl is tilted using the hand wheel (or via motor) and the product is discharged and collected for further processing.

Features and Benefits

- Two self cleaning counter rotating shafts, sigma blade design

- Product contact parts in 304 stainless steel

- Product discharge by rotating manual wheel

- Heating/cooling jacket with inlet/outlet connections

- Jacket equipped with thermowell/thermometer

- Bowl equipped with safety grid, limit switch, and cover

- Controls integrated on machine frame (optional)