- Home

- Powder Handling

- Extruders

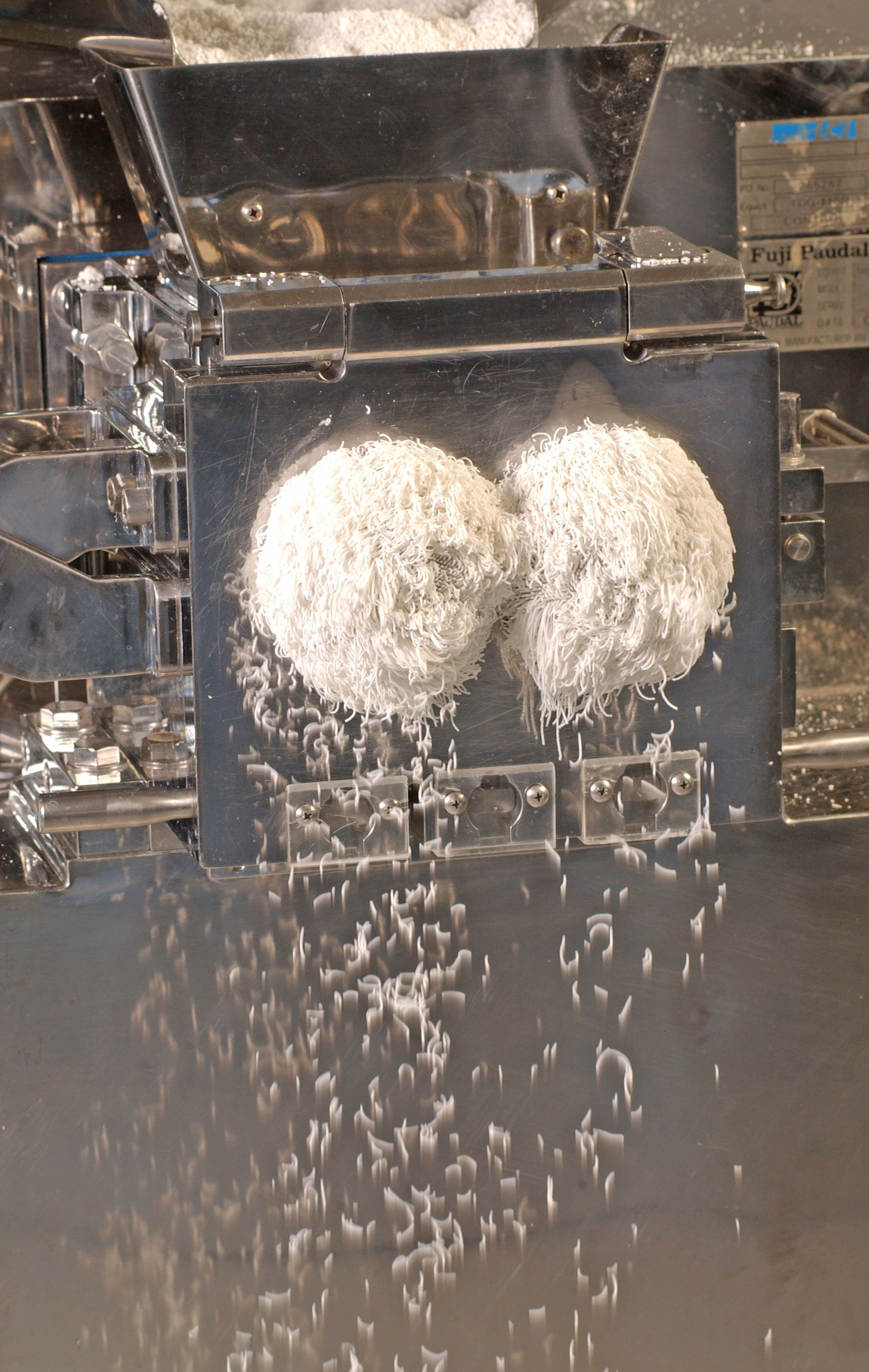

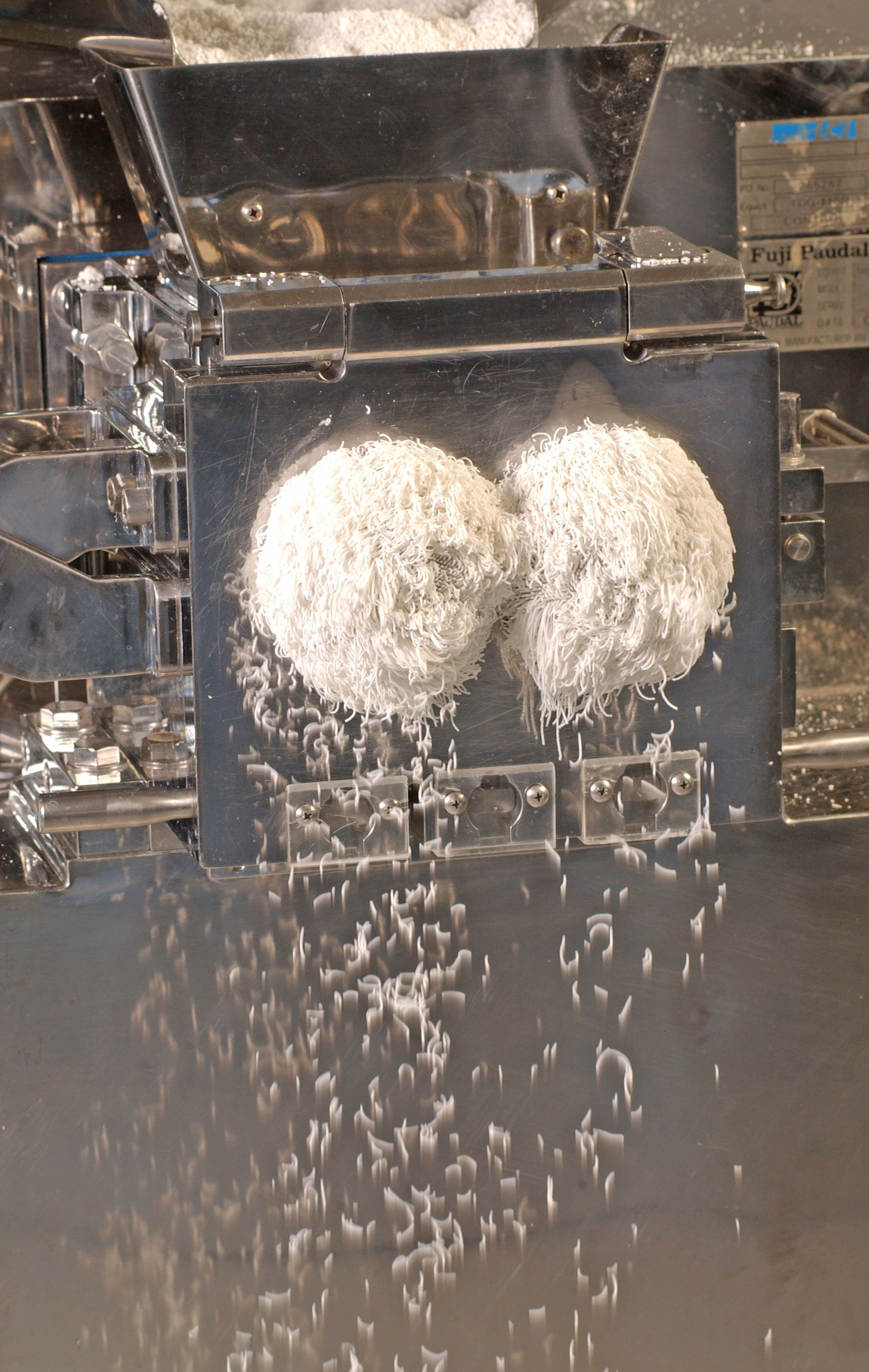

Twin Dome Granulator Extruder

Twin Dome Granulator™ Extruder

The patented Twin Dome Granulator (TDG) Extruder offers high capacity twin screw extrusion through a hemi-spherical die that allows for uniform extrusion pressure and shear.

The wet mix, which is typically prepared in a kneader, pug mixer or high shear granulator (pharma), is metered into the feed hopper by a feeder or hand fed. Twin screws transport the wet mix to the extrusion zone where it is then wiped through a dome die (screen) to produce well formed, cylindrical extrudates of a controlled diameter. The extrudates break off by their own weight and are collected for the next processing step.

Features and Benefits

- Low pressure extrusion with negligible heat generation

- Screw transport ensures plug flow, first in first out

- Easy-to-clean clamshell design extrusion chamber for easy access to process parts

- Hydraulic clamping system for ease of disassembly

- Minimal holdup volume

- Easy scale-up

- High yield

- Better particle size distribution

- Improved flowability

- Excellent process repeatability

Applications

Agricultural Chemicals

LCI’s low pressure extrusion systems are extensively used to produce extruded pesticides in the form of Water Dispersible Granules (WDG) and Water Soluble Granules (WSG).

Products include:

- Herbicides

- Insecticides

- Fungicides

- Biocides

Commonly extruded pesticides:

- Atrazine Ametryn

- Amicarbazone Carfentrazone

- Chlorimuron Dicamba

- Diuron Flumioxazin

- Glyphosate Isoxaflutole

- Metribuzin Sulfentrazone

Other Products

- Animal antibiotics

- Feed additives (enzymes)

- Tobacco

- Nutraceutical intermediates

Pharmaceutical

LCI's low pressure extrusion systems in conjunction with our spheronization systems are used to produce high API drug pellets.

- Controlled release pellets for encapsulation

- Delayed release enteric coated pellets

- Sustained release pellets

- Multi-particulate systems

- Multi-unit erosion matrix pellets

- Pellets for special tableting applications

- Immediate release pellets for sachets

Industrial Chemicals

- Catalysts (zeolites)

- Pyrotechnics

- Specialty detergents

- Detergent additives (enzymes)

- Absorbents

- Sodium benzoate

Food & Beverage Additives

- Flavors

- Beverage preservatives

- Colorants

- Enzymes