- Home

- Powder Handling

- Circle Feeder

Mass Flow Feeder

Mass Flow Feeder

If your product is difficult to meter, our mass flow feeder's unique operating principle provides reliable, accurate feeding where others fail.

- Fine powders

- Granular materials

- Wet materials

- Fiberous materials

- Cohesive materials

- Flakes

- Fluff

- Pellets

- and More

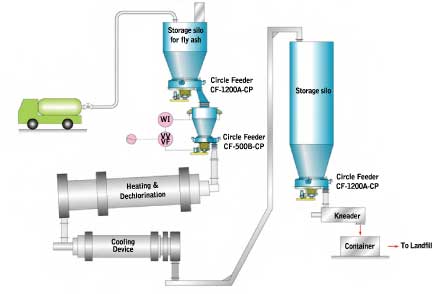

Volume Reduction Facility for Fly Ash

Fly ash is compressed to reduce its volume and prevent the release of toxic substances. The heating / dechlorination machine heats the fly ash to a high temperature and harmful substances such as dioxin are removed. Our mass flow feeder with a loss-in-weight system was required for uniform feed.

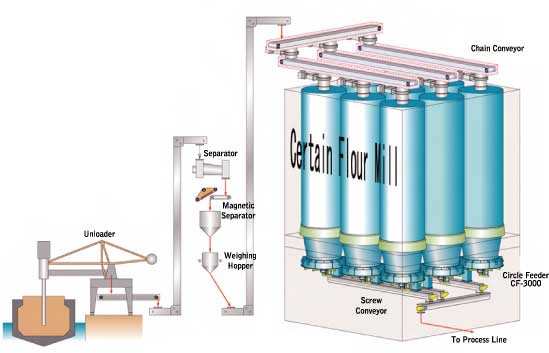

Large Silo Storage for Bran

Bran, the outer husk of cereals, is typically used to make live stock feed and fertilizer. Recently, bran has also been used as an additive to foaming agents for use in health food products and packaging.

When a large quantity of bran is stored in a silo, it is difficult to discharge because the material's high pressure causes bridging at the lower part of the silo. This is aggravated by bran's low bulk density.

Our mass flow feeder is ideal for discharging bran from large silos due to its large inlet diameter which prevents bridging. Over 180 Circle Feeders are in use in this application.

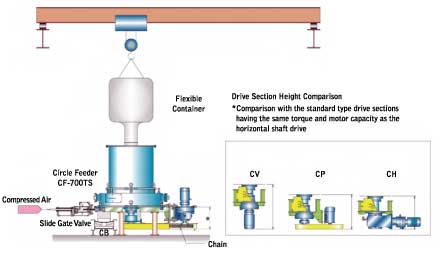

Horizontal Shaft Drive

The coupling can be specially designed to have the lowest possible drive section height for this type, in order to meet the limited installation space.

The drive section height can be reduced further than that of the CV, CP, and CH types provided in the standard specifications.