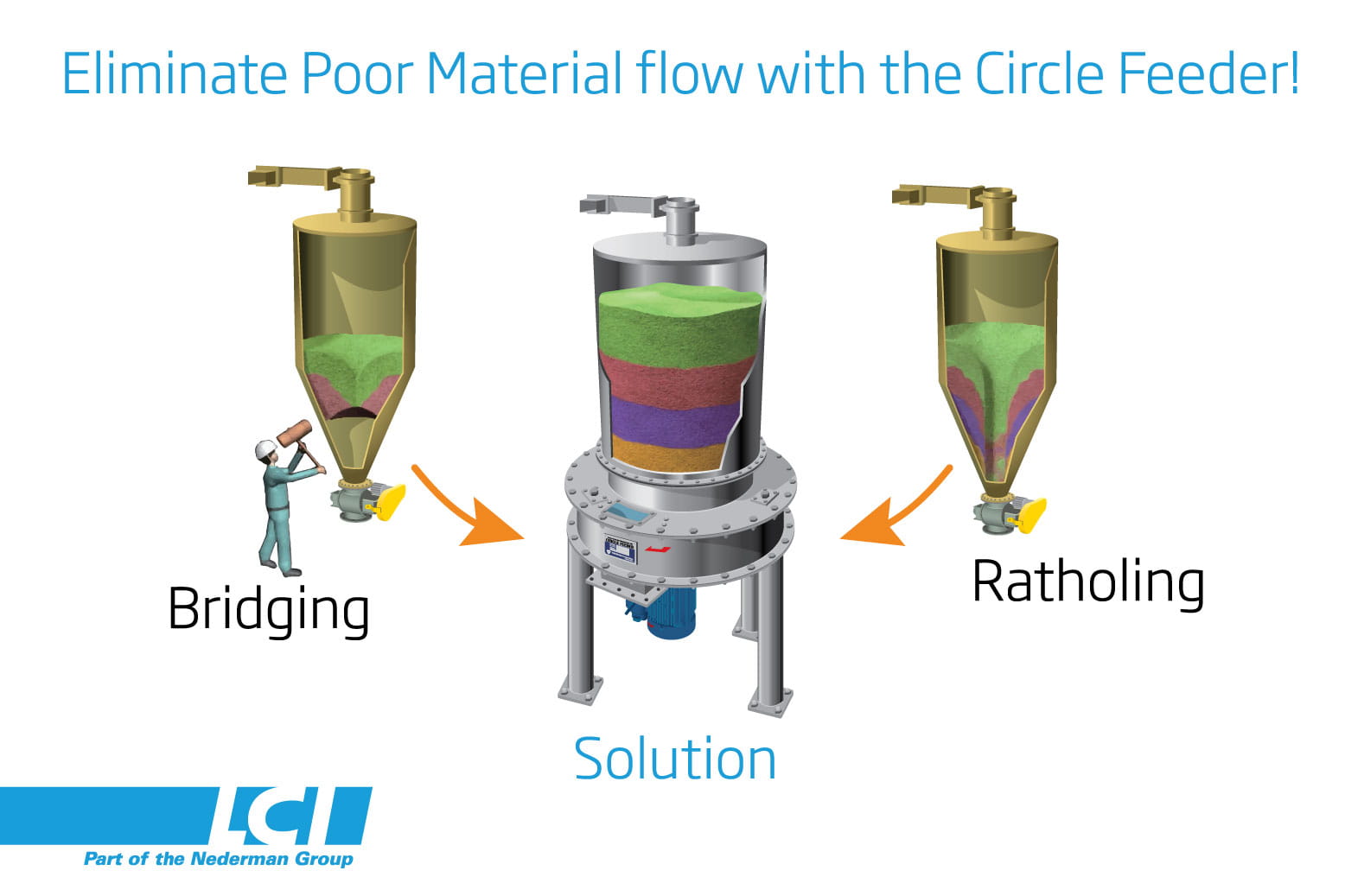

The large open inlet exceeds most materials’ critical arching diameter, preventing bridging and ratholing. Even high viscous material can be fed through the feeder and discharger smoothly. Its unique construction fulfills allows for quantitative dosing steadily and evenly. The Circle Feeder can be manufactured with several outlets for “one to multiple” feeding, which saves on the amount of equipment, space and maintenance costs. The feature: first-in first-out, last-in last-out, free from bridging and segregation, compact construction, easy maintenance.

Segregation is the uneven distribution of components in powder material that occur during flows of the material due to differences in physical properties of its components. Segregation is difficult to check visually, and the adverse effects resulting from segregation during storage and handling of powder are diverse. Circle Feeder is the premier choice feeder that can prevent the segregation during mass flow discharging.

The Circle Feeder can be used as a material feeder, large industrial feeder, laboratory feeder, powder feed, volumetric feeder, and dry chemical feeder. The Circle Feeder can also be used in place of the screw feeder, belt feeder, bulk feeder, and hopper feeder. It has also been used as a solution in place of the rotary feeder, weigh feeder, powder silos, and within powder feed systems.