The unique features of the DOME-EX allow it to continuously produce micro-granules of uniform diameter and hardness. This continuous processing concept eliminates the need for slow, batch granulation (e.g. high shear, and fluid bed granulators), and yields a streamlined, high capacity, more consistent (minimal variability) process.

The DOME-EX System:

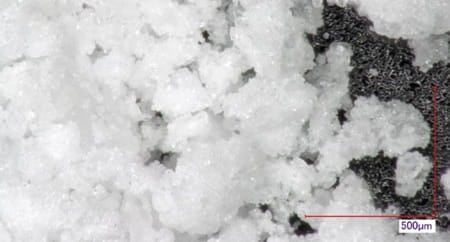

Pre-blended powders are continuously metered into the DOME-EX using a powder feeder (sold separately). Liquid is added using a peristaltic pump. The DOME-EX twin screws intimately knead/mix the material and transport it continuously into the inlet of the vertical extruder equipped with a dome die. The wet mass is gently wiped though the dome die producing fine, dense, cylindrical granules of a specific diameter. The prepared wet material is manually fed.

**Powder feeder and liquid pump sold separately