LCI Thin-Film High Viscosity Processors concentrate viscous solutions such as polymers and food with indirect and frictional heat transfer, mechanical agitation and transport of the thin product film under both vacuum and positive pressure conditions.

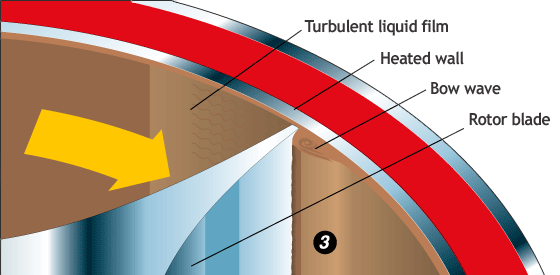

Product enters above the heated zone and is evenly distributed over the unit's inner surface by the rotor. Pitched blade elements transport the viscous material down the thermal surface and promote heat transfer.

Volatile components are rapidly evaporated and flow either counter-currently or co-currently to the liquid flow through the unit, depending on the application. In both cases, vapors are ready for condensing or subsequent processing.

Nonvolatile components are discharged at the bottom of the high viscosity processor with a specially-designed discharge section.

Its relative short residence time and open, low pressure-drop configuration allow continuous, reliable processing of many heat-sensitive, viscous materials without product degradation.