Reproduced with permission from CEP(Chemical Engineering Progress) December 2004. Copyright © 2004 AIChE.

Evaluate product characteristics and process requirements to select among the various evaporator designs.

By William B.Glover - LCI Corporation

Evaporators are used in a wide range of processes, including pharmaceuticals, foods and beverages, pulp and paper, chemicals, polymers and resins, inorganic salts, acids, bases, and a variety of other materials. There are many types and variations of evaporators,and the best for a particular application depends on the product characteristics and desired results.

This article first explains the process requirements that an evaporator must meet, and discusses the critical operational and product characteristics and their effects on evaporator selection. It then reviews the various types of evaporator designs, their modes of operation, features, advantages and limitations, and it provides guidance on how to select an evaporator for a particular application.

Evaporation is an operation used to concentrate a solution of a nonvolatile solute and a volatile solvent, which in many cases is water. A portion of the solvent is vaporized to produce a concentrated solution, slurry or thick, viscous liquid.

Evaporation differs from drying in that the residue is a flowable liquid instead of a solid. Evaporation is different from distillation in that there is no attempt to separate the vapors into individual components.

Either the vapor or the concentrate stream, or both, may be the desired product (1).Therefore, the evaporator should be designed to provide a clean separation of the vapors from the condensate and the feed.

An evaporator consists of a heat exchanger or heated bath, valves, manifolds, controls, pumps and condenser. The most common designs are jacketed tanks, tubular heat exchangers, plate-and-frame heat exchangers, and agitated thin-film evaporators.

A properly designed evaporator must, at a minimum:

Critical operational and product characteristics of the solution to be evaporated have a major effect on the selection of the evaporator type most suited for the application.

Many foods, pharmaceuticals, chemicals and resins are heat- or temperature-sensitive and require either low heating temperatures or a short residence time exposed to the heat, or both. This can be accomplished by a combination of minimizing the volume of product in the evaporator at anyone time, minimizing the time in the evaporator, and reducing the product’s bulk boiling temperature by operating the evaporator at reduced pressures. Reducing the internal operating pressure may also allow operation at lower heating temperatures while still maintaining a reasonable heat-transfer driving force (the temperature difference between the boiling point of the bulk product and the temperature of the heating medium).

Fouling of the heat transfer surfaces is usually caused by solids in the feed, precipitating solids in the concentrate, or degradation of the product. A slow buildup of a film on the heat transfer surfaces will cause a gradual reduction in the overall heat-transfer coefficient. Eventually this will require shutdown of the process and cleaning of the heat transfer surfaces, which results in production downtime and additional maintenance labor.

Product foaming during vaporization is common. It may range from a small amount of unstable foam that breaks easily to a very stable foam that is difficult to break and tends to fill the entire void of the evaporator system. Foaming can often be minimized by special designs for the feed inlet (separation of feed from the vapor stream) and the vapor/liquid separation area(special disengaging designs). Also, reducing the boiling intensity of the liquid on the heat transfer surface (by operating at a lower temperature or at a higher pressure) and reducing the vapor velocity in the tubes may significantly reduce foaming.Where the product purity specifications allow, introduction of an antifoam may solve or greatly reduce the problem.

The properties of the concentrate may change as the solids concentration increases. Solids may plug tubes, causing loss of heat transfer surface, in turn resulting in reduced heat-transfer rates and requiring downtime for cleaning. Solids increase the tendency to foul the heating surface, which reduces the heat-transfer coefficient and boil-up rate. An increase in solids may also increase the concentrate viscosity, which affects the overall heat-transfer coefficient, reducing capacity.

Any increase in the viscosity of the concentrate will reduce the overall heat-transfer coefficient.

In general, there must be enough liquid passing through the evaporator to keep the heat-ed walls wetted. Lack of wall wetting and fluid velocity may cause serious fouling and salting of solids on the heat transfer surfaces, causing reduced heat transfer and possible product quality degradation as a result of hot spots on the heating surface. In processes where high distillate-to-concentrate ratios are required, recycling of some amount of the concentrate may be required.

Consideration must be given to the vapor velocity in the evaporator tubes and heating jackets. Adequate velocities are needed to produce sufficient heat-transfer coefficients with-out exceeding limitations on pressure drop, erosion and entrainment. Careful attention must be paid to the requirements of the vapor/liquid separator for separation efficiency and pressure drop.

The heat transfer medium (hot oil or steam) may impact the selection of the type of evaporator. Liquid-heated evaporators typically have lower overall heat-transfer coefficients and require more heat transfer area. If the product is temperature-stable, then hot oil heating may allow higher temperatures and overcome the lower heat-transfer coefficient. This, in some cases, could allow the use of a smaller evaporator.

A major consideration in evaporator selection may be the required materials of construction. The heat-transfer surface material is extremely important, because it not only affects the overall material cost, but also determines the thermal conductivity of the material, which impacts the overall heat-transfer coefficient and the required surface area.

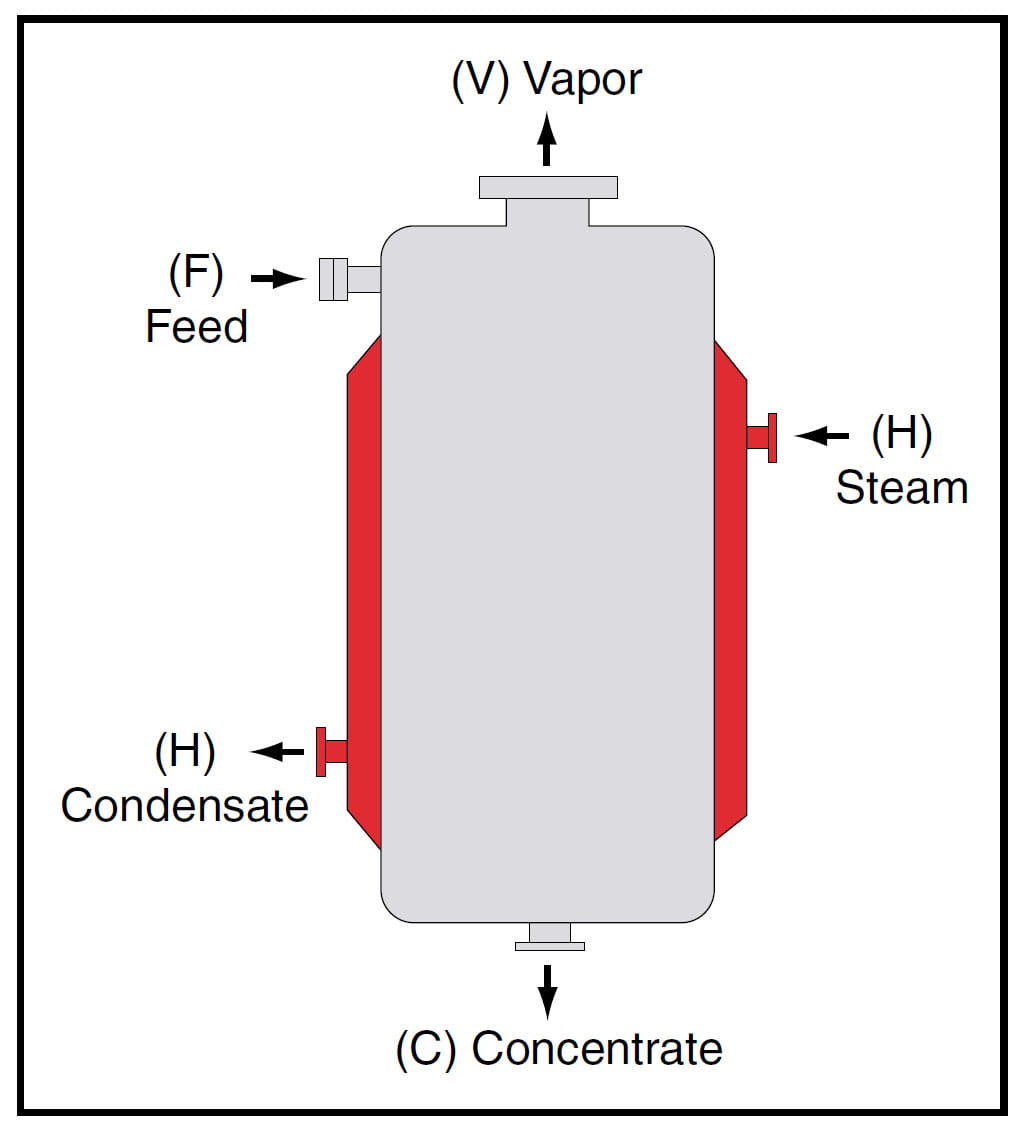

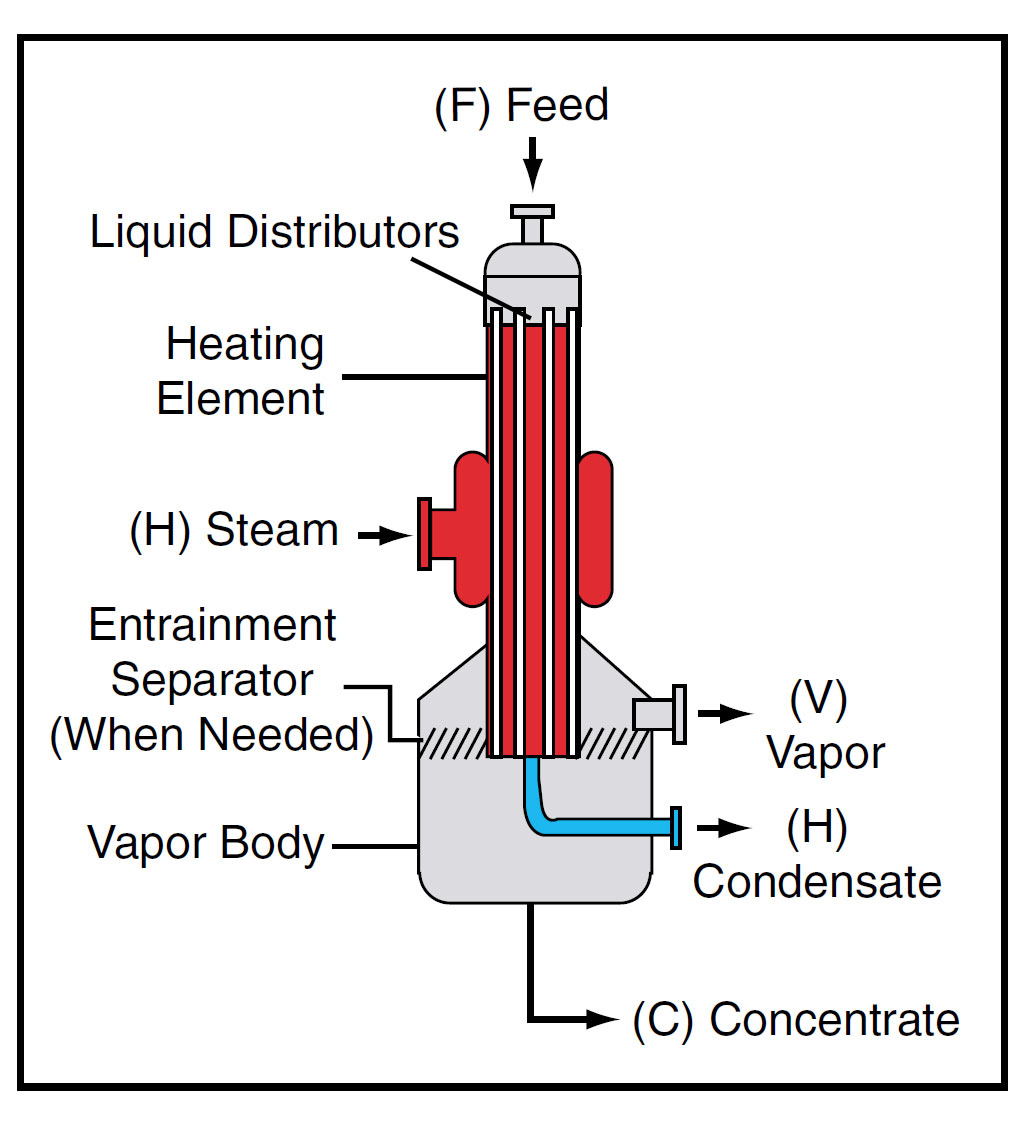

The simplest, and one of the oldest, designs is the batch evaporator (Figure 1). It consists of a jacketed vessel that is heated with a vapor or liquid heating medium (H). The product is metered into a tank to a specified level through a feed nozzle (F). Heat is applied and the batch is allowed to heat to its boiling point; vapors are removed until the desired concentration is reached. The heat is then removed. The concentrate is drained or pumped out of the tank through a nozzle (C).

Batch evaporation is not well-suited for temperature-sensitive products. First, the residence time is usually long. Also,the static head of the liquid increases the boiling point of the product at the bottom of the tank; this may be overcome somewhat by operating the tank under vacuum to reduce the boiling point of the batch.

Heat-transfer coefficients are usually low, and the heat transfer area is low for the volume occupied by the tank.Because product movement is only via natural circulation,temperature-sensitive products or products containing solids tend to foul the heated surfaces. Heat-transfer coefficients can be improved and fouling reduced by placing an agitator into the tank(stirred batch).

The batch evaporator is still used for many processes, particularly those that involve small batches of products that are clean, viscous,and not heat-sensitive.

Figure 1. A batch evaporator is one of the simplest designs.

Natural circulation is normally used for simple applications where the product is clean and temperature-stable (whereas forced-circulation evaporators are used for viscous, salting and scale-forming products) (2).The most common natural-circulation tubular evaporators are horizontal tube, calandria (or short) vertical tube, and long vertical tube.

The horizontal tube evaporator (Figure 2) is the oldest type of chemical evaporator, although other improved types are now more commonly used.

The horizontal tube evaporator is the only type of chemical evaporator in which the heating medium is inside the tubes.

The principal advantage of horizontal tube evaporators lies in the relatively small headroom they require. The horizontal evaporator is least satisfactory for fluids that form scale or deposit salt (which would build up on the outside of the tube). It is well-suited for processes where the final product is a liquid instead of a solid, such as sugar syrups where the large volume of liquid stored in the evaporator allows a close adjustment of the final density by changing the hold-up in the evaporator.

Figure 2. The heating medium flows inside the tubes of a horizontal tube evaporator.

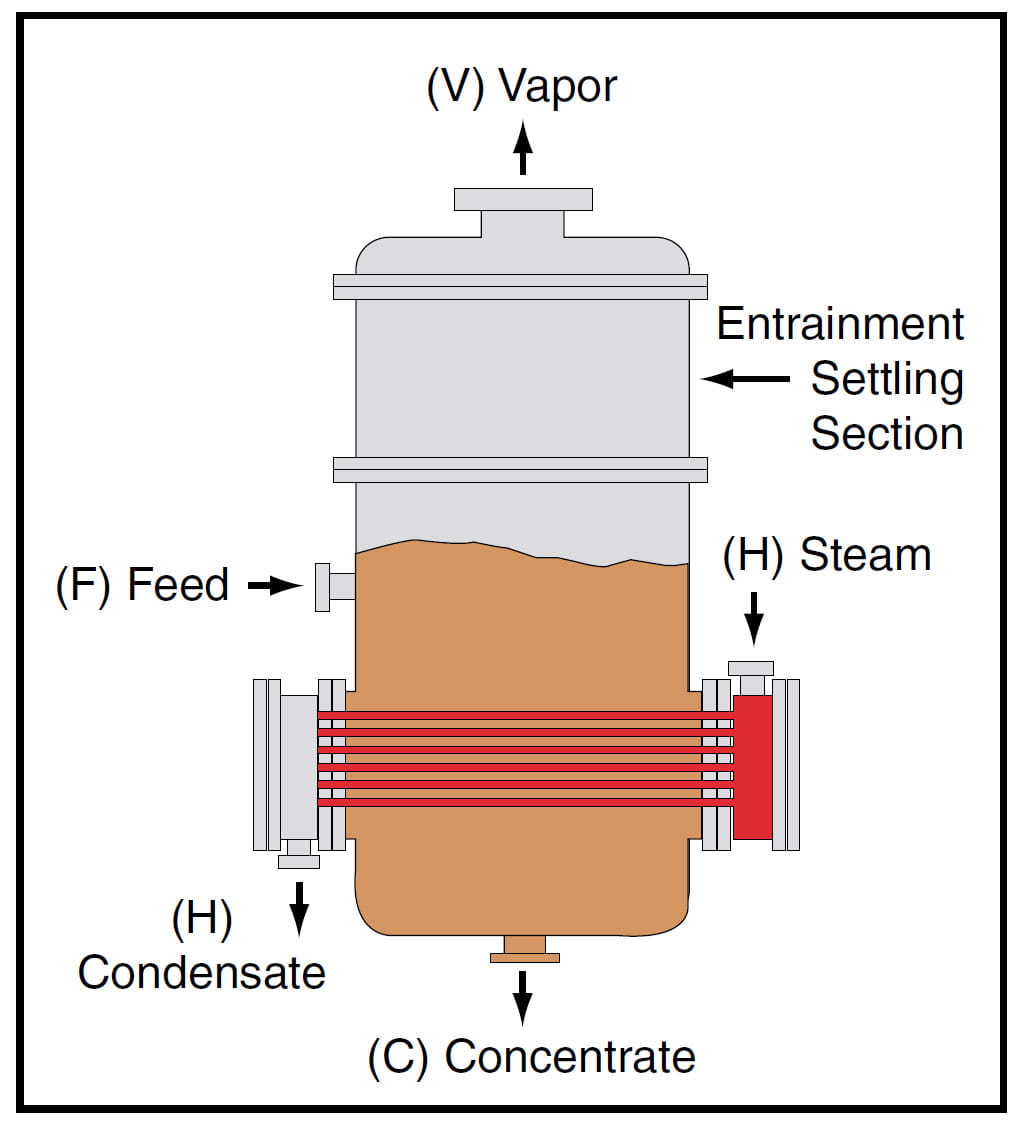

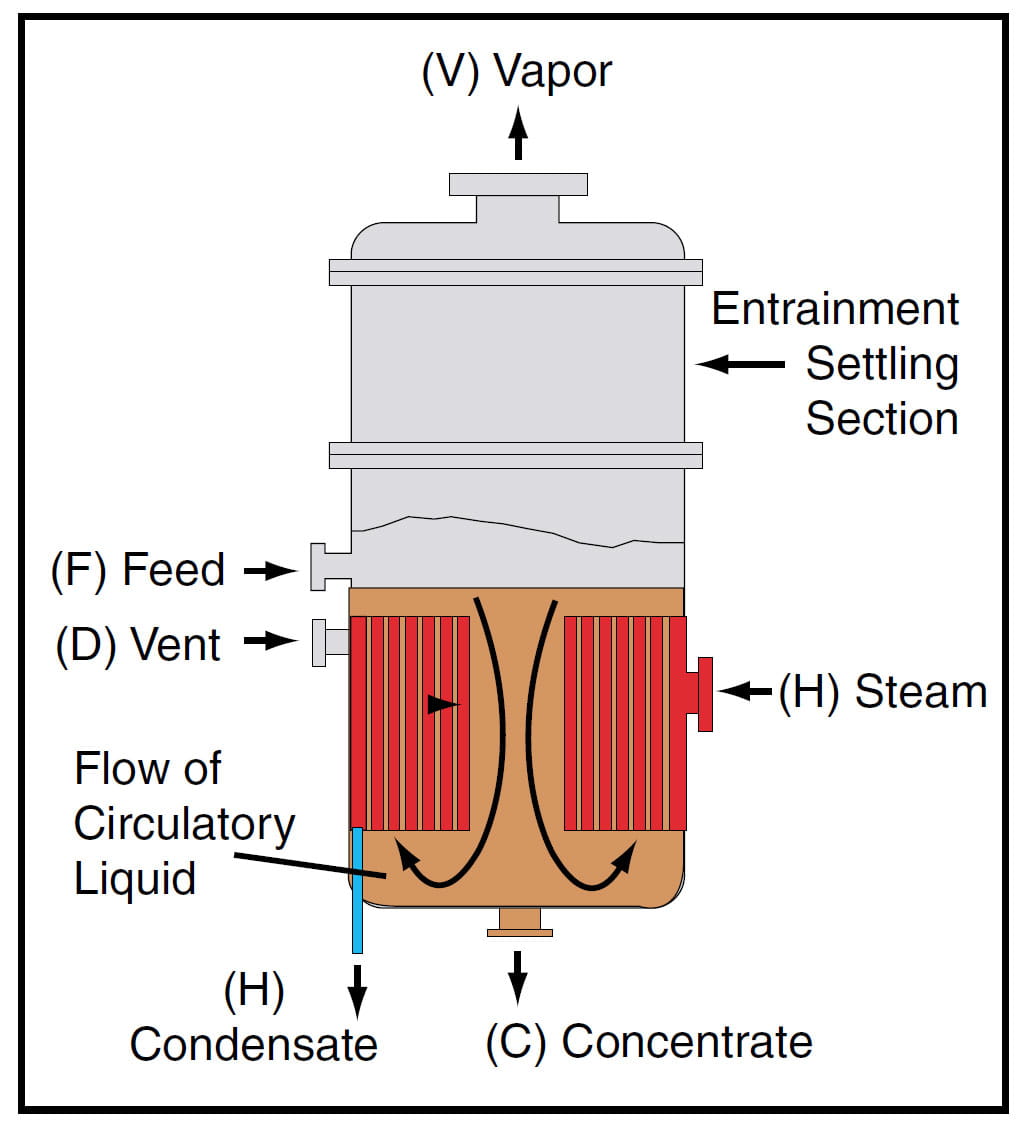

The short-tube, or calandria, vertical evaporator (Figure 3) is one of the earliest types still in widespread commercial use (3).

The short-tube evaporator is characterized by tubesheets (A)extending across the body and a central downspout (B). Tubes are rolled between two tubesheets and steam is introduced as shown in Figure 3. The liquid is in the tubes and the heating medium outside the tubes. As the liquid boils, it rises up through the tubes and returns through the central downtake. Condensate is removed from any convenient place on the bot-tom of the tubesheet (such as C), and the non-condensed gases are usually vented from somewhere near the upper tubesheet(e.g.,D). The exact positions of the feed (F) and discharge (C)are variable, but the positions shown in Figure 3 are fairly typical.

The operating level of the liquid is normally near the top of the top tubesheet. The cross-section of the downtake is usually between 75% and 150% of the cross-sectional area of the tubes. The tubes may range from 1 in. to 4 in. in diameter and from 30 in. to 6 ft in length; general practice favors about 2-in.-dia. and 5-ft-long tubes. (4).

Circulation and heat transfer in this type of evaporator are strongly affected by the liquid level (3).Boiling in the tubes induces circulation past the heating surface. Circulation is created by the difference in specific gravity between the bulk liquid and the heated liquid and vapor generated inside the tubes.The highest heat-transfer coefficients are achieved when the level is only about half-way up the tubes. Reduction below the optimum level results in incomplete wetting of the tube wall,with a consequent increase in fouling tendency and a rapid reduction in capacity. When this type of evaporator is used with a product that can deposit salt or scale, it is customary to operate with the liquid level appreciably higher than optimum and usually above the top tubesheet (3).

Advantages of the short-tube vertical evaporator include:

However, heat transfer depends greatly on the effect of viscosity and temperature, it is not for use with temperature-sensitive materials, and it is unsuitable for crystalline products unless agitation is provided.

One principal use of the short-tube vertical evaporator is the concentration of sugar cane juice.

Figure 3. In a short-tube vertical evaporator, the process liquid is inside the tubes and the heating medium outside the tubes.

The long-tube vertical, or rising-film, evaporator (Figure 4) is one of the most widely used tubular evaporators. It can be built as a large single unit, partially due to the high heat-transfer performance exhibited undermost conditions, and partially because of the simplicity and low cost of construction. It is basically a shell-and-tube heat exchanger mounted to a vapor/liquid separator. It requires little floor space,but high head-room. Tubes are usually 1–2-in.-o.d. and 12–32-ft long (1).

The dilute feed enters at the bottom of the tubesheet and flows upward through the tubes, with the heating medium on the shell side. In the lower portion of the tubes, the feed is heated to its boiling point. At some distance further up, bubbles form on the tubes and boiling begins, increasing the linear velocity and the rate of heat transfer. Near the top of the tubes, the bubbles grow rapidly. In this bubble zone, slugs of liquid and bubbles rise quickly through the tubes and are discharged at high velocity from the top, where they impinge on a liquid/vapor separator that tends to break any foam.This allows the use of this type of evaporator for products that tend to foam (1).

Advantages of the long-tube vertical evaporator are:

Disadvantages are:

Some of the common uses of long-tube vertical evaporators are the concentration of cane sugar syrups, black liquor in paper plants, nitrates and electrolytic tinning liquors.

Figure 4. Feed flows upward through the tubes and heating medium flows downward on the shell side of along-tube rising-film vertical evaporator.

When designing a tubular evaporator, one should evaluate the value of mechanical recirculation. At first glance,the addition of a pump and additional controls will add to the installation, operating and maintenance costs.

However, recirculation of part of the concentrate back to the feed stream may increase the heat transfer enough to allow the evaporator’s size to be reduced considerably,resulting in lower total costs.

The increased velocity of liquid in the tubes (typically in the range of 4–10 ft/s) may also reduce or eliminate any potential fouling, thereby maintaining capacity and reducing downtime. In a falling-film evaporator, it can improve the liquid loading at the bottom of the tube, allowing higher distillate-to-feed ratios.

In most cases where the feed contains solids or crystallization is present, forced circulation should be used. The advantages of using a forced-circulation evaporator are:

The primary disadvantages of forced circulation are:

Typical applications where forced circulation should be used are sodium sulfate, urea, sodium chloride, ammonium sulfate, magnesium chloride, citric acid and caustic potash.

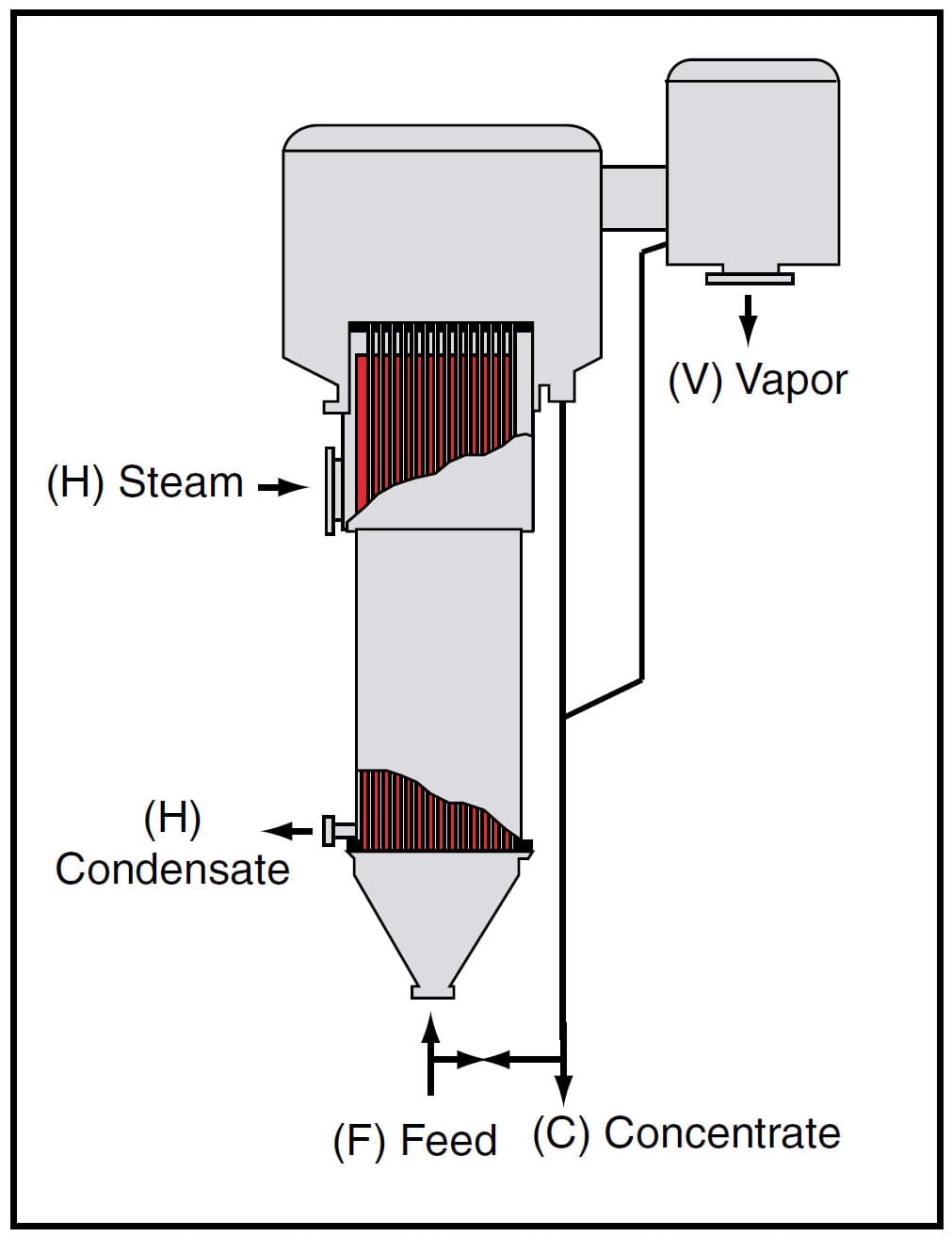

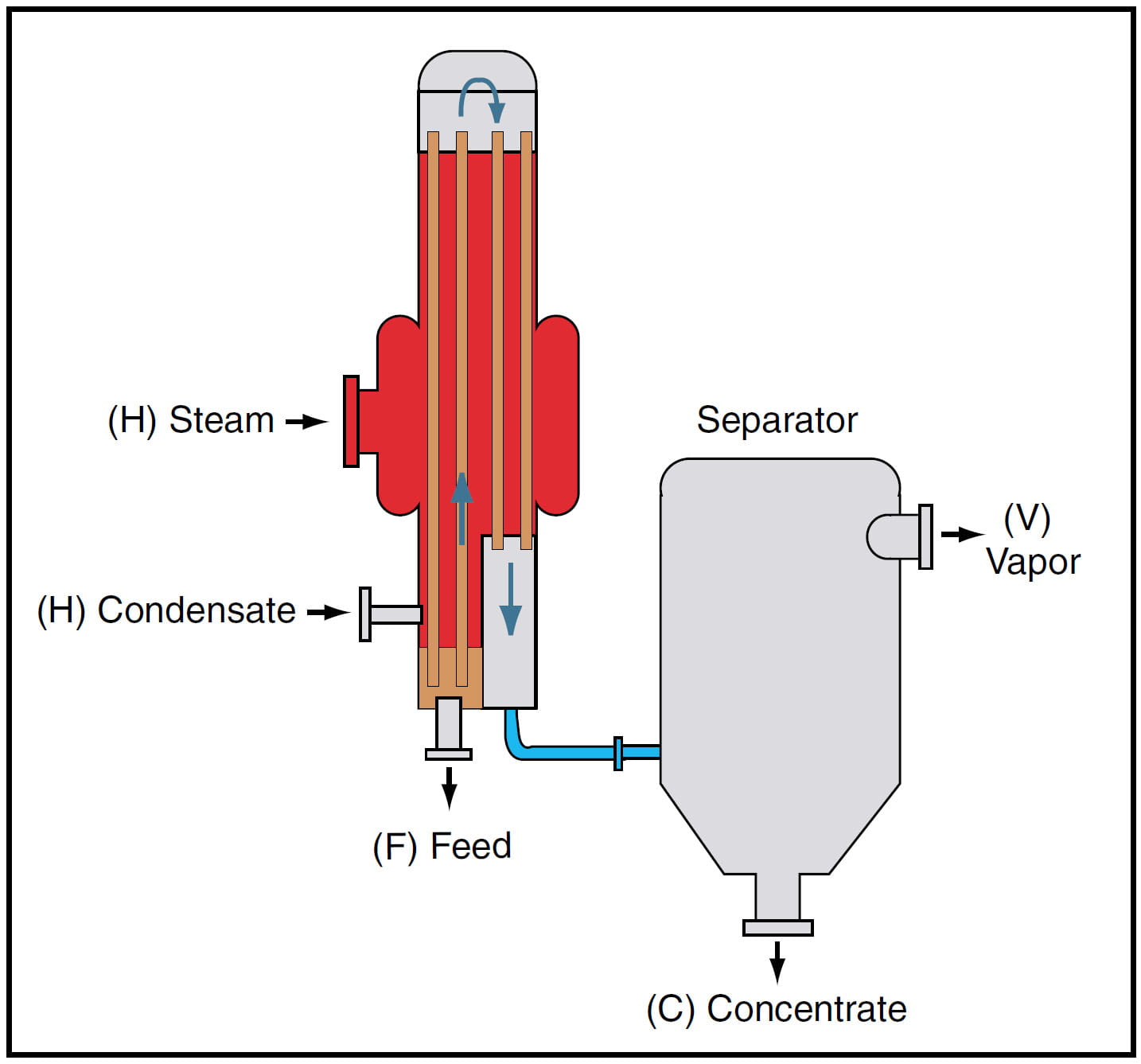

The long-tube falling-film evaporator (Figure 5) is a variation of the long-tube rising-film evaporator, in which the equipment is turned upside down so the tubular heat exchanger is on top of the vapor/liquid separator section.Feed enters at the top of the evaporator, where specially designed distributors evenly distribute the feed into each of the tubes. Distribution of the feed is very critical and there are many designs for the distributors, but generally most are built around some type of perforated plate placed over the top tubesheet.

The falling-film evaporator has the advantage of gravity pulling the film downward. This results in a thinner, faster-moving film and gives high heat-transfer coefficients and short residence times in the heating zone.

The falling-film evaporator is particularly useful in applications where the temperature driving force between the heating medium and the liquid is small (less than 15°F). The combination of the ability to function at low temperature differences and short residence times makes the falling-film evaporator suitable for use with temperature-sensitive products.

The design of the vapor/liquid separator at the bottom of the tubesheet depends greatly on the properties of the material being processed and the operating conditions. The ratio of the liquid distilled to the feed rate is very critical to a falling-film evaporator. High distillation splits utilizing a single-pass process could reduce the flow of liquid to where it is inadequate to keep the tubes wetted near the bottom. This would subject the tubes to potential fouling by degraded product.

The primary advantages of falling-film evaporators are:

The primary disadvantages are:

Typical applications for falling-film evaporators are the concentration of dairy products (such as whey, milk protein, skim milk, cream and hydrolyzed milk), sugar solutions, urea, phosphoric acid and black liquor.

Figure 5. The falling-film evaporator is a variation of the long-tube rising-film design, in which the tubular heat exchanger is on top of the liquid/vapor separator.

The rising-film and the falling-film evaporators are sometimes combined into a rising/falling-film evaporator to incorporate the advantages of both (Figure 6). When a high ratio of evaporation to feed is required and the concentrate may be viscous, a tube bundle can be divided into two sections, with the first functioning as a rising-film evaporator and the second as a falling-film evaporator (5).

Feed enters at the bottom of the tubesheet of the rising-film portion. Boiling starts as the liquid rises through the tubes. A mixture of liquid and vapor is discharged and redistributed over the top of the tubes for the falling-film pass. The vapors from the rising-film pass aid in the distribution of liquid on the tubes, and increase the velocity of the liquid, which increases heat transfer. The mixture of vapor and liquid from the downflow is separated in an external separator.

The rising/falling-film evaporator’s advantages are:

Disadvantages include:

They are best applied when handling clear fluids or foamy liquids, and when large evaporation loads are required. (5).

Figure 6. A rising/falling-film evaporator combines the advantages of both the rising-film and falling-film designs.

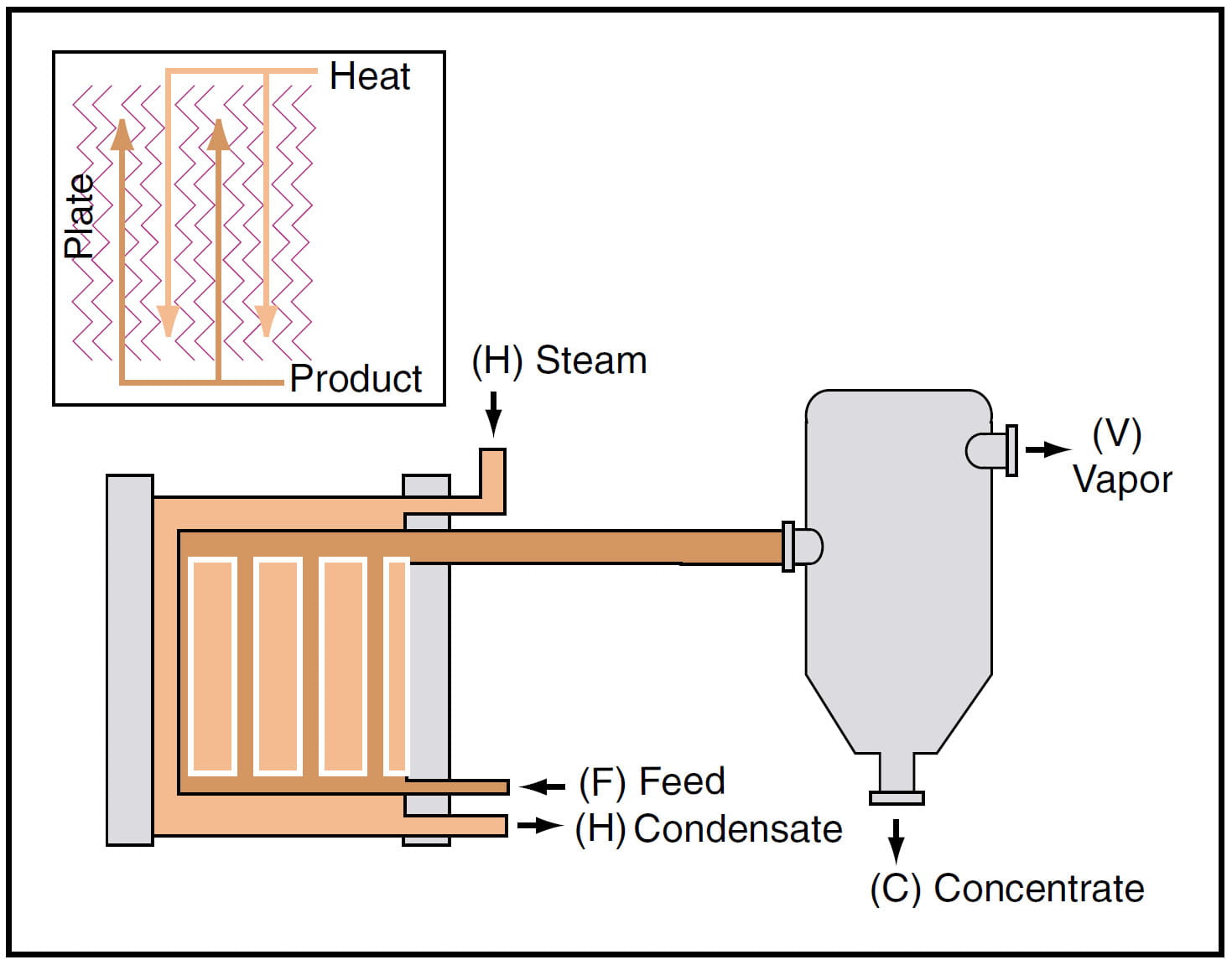

The gasketed plate-and-frame evaporator (Figure 7) is constructed by mounting a number of embossed plates with corner openings between a top carrying bar and bottom guide bar. The plates are gasketed and arranged to form narrow flow passages when a series of plates are clamped together in the frame.

Fluids are directed through the adjacent layers between the plates, either in series or parallel, depending on the gasketing. The gaskets confine the fluids and prevent them from escaping into the atmosphere. The heating medium flows between every other plate.

These systems may be operated as rising-film, falling-film or rising/falling-film evaporators.

With appropriate design for a specific application, very high velocities and heat-transfer coefficients can be reached. The high velocities help to minimize scale or salting of the heating surfaces. The volume held in the plate evaporator is very small compared to the large available heat-transfer surface. To optimize the heat transfer and maintain low bulk temperatures, plate evaporators are often operated under reduced pressure.

Advantages of gasketed plate-and-frame evaporators are:

A major disadvantage is the large gasketed area. Leakage can be avoided by selecting the proper gasket for the application and following proper assembly procedures (5).

Typical applications of gasketed plate evaporators are stripping applications, removing monomers from polymers and deodorization.

Figure 7. A gasketed plate-and-frame evaporator may be operated in arising-film, falling-film, or rising/falling-film mode.

One of the more useful types of evaporators for difficult-to-handle materials is the agitated thin-film evaporator(Figure 8). Although tubular evaporators have been used successfully with a variety of materials, they have been less successful with heat-sensitive, viscous,fouling or high-boiling liquids. Degradation due to long residence time,fouling of the heat trans-fer surfaces, plugging of tubes, and low heat trans-fer and high pressure drops due to high viscosities are common problems.

Agitated thin-film evaporation successfully overcomes problems with difficult-to-handle products. Simply stated, the method quickly separates the volatile from the less volatile components using indirect heat transfer and mechanical agitation of the flowing product film under controlled conditions.The separation is normally made under vacuum conditions to maximize the temperature difference while maintaining the most favorable product temperature, as well as to maximize volatile stripping and recovery.

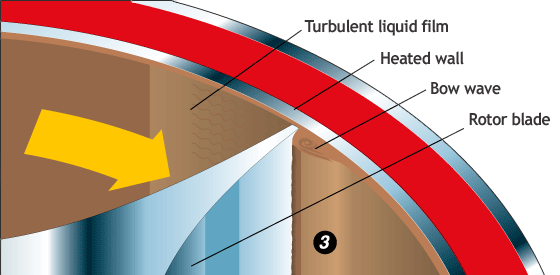

Various thin-film evaporator designs are commercially available. The agitated thin-film, or wiped-film, evaporator consists of two major assemblies — a heated body and a rotor.Both vertical and horizontal designs are available. The rotor may be one of several designs, with the clearance between the rotor and the heating jacket wall varying from a fixed distance to essentially zero and actually wiping the wall.

The majority of thin-film evaporators in operation today are of the vertical, cylindrical, fixed-clearance rotor design.The feed enters the unit above the heated zone and is distributed evenly over the inner circumference of the body wall by the rotor (Figure 9). Product spirals down the wall, while bow waves developed by the rotor blades generate a highly turbulent flow, leading to high heat flux. Volatile components evaporate rapidly. Vapors can flow either co-currently or counter-currently, and are ready for condensing or subsequent processing as they leave the unit. Nonvolatile components are dis-charged at the bottom outlet. Continuous washing by the bow waves minimizes fouling of the thermal wall, where the product or residue is most concentrated.

The combination of short residence time, narrow residence time distribution, high turbulence, and rapid surface renewal permits the agitated thin-film evaporator to successfully handle heat-sensitive, viscous and fouling materials. A “standard” thin-film evaporator can normally process materials with viscosities of 1–50,000 cP. Special transporting-rotor designs can be operated in the range of 50,000 to 20 million cP. Low product inventory and operation at near-equilibrium conditions in the process zone are important for highly reactive products.

Agitated thin-film evaporators have a wide processing flexibility, and a single system can often be designed to process different products under varied operating conditions (6). Normally, a thin-film evaporator is operated under reduced pressures in the range of 2–250 mmHg abs. Either steam or liquid heating medium is used to heat the evaporator.

Advantages of an agitated thin-film evaporator are:

A disadvantage is its higher cost compared to standard evaporation equipment. In addition, staging or vapor recompression for energy recovery are not practical.

Agitated thin-film evaporators are typically used in such applications as:

The mechanical and process technology for mechanically agitated thin-film evaporation systems is proven and reliable, and should be considered whenever an application proves difficult for conventional tubular evaporators. Frequently, a tubular and agitated thin-film evaporator combination is the optimum solution (6).

Figure 8. Agitated thin-film, or wiped-film, evaporators are well-suited for processing difficult-to-handle materials.

Figure 9. A rotor distributes the feed evenly over the inner circumference of the body of the wiped-film evaporator.

Before the process and equipment can be evaluated,the requirements, specifications, and value for a marketable product must be determined. Then, the general process specifications required to produce the marketable product must be determined. The process should make a quality product with a good yield and minimum waste. The following factors should be considered:

Choosing the best evaporator may be easy or may be complex. Product characteristics such as high viscosities or heavy solids gives some direction. However, for many simple applications, all or many of the different types will handle the process equally well. In such cases, the choice may be dictated by such factors as capacity, small batch production, past plant experience, available space, operator requirements, utility requirements, maintenance required, and/or cost.

The table below provides some guidance in the selection of an evaporator for a particular application.

| Product characteristic selection criteria for evaporators. | |||||||

|---|---|---|---|---|---|---|---|

| Type of Evaporator | Clean | High Capacity | Solids or Crystals | Fouling | Foamy | Temperature Sensitive | Viscous |

| Batch | X | X | |||||

| Horizontal Tube | X | ||||||

| Vertical Short Tube | X | ||||||

| Vertical Long Tube | X | X | |||||

| Rising Falling Film | X | X | X | ||||

| Falling Film | X | X | X | X | X | ||

| Forced Circulation | X | X | X | X | X | ||

| Plate | X | X | X | X | X | X | X |

| Agitated Thin Film | X | X | X | X | X | X | X |

Typically, the most economical choice for low capacity or multi-product batch production is the batch or stirred-batch evaporator. It is simple, inexpensive,and will handle a number of products with variable characteristics and operating conditions. It may require more cleaning time, but it is typically a low-maintenance system.

Where high capacity is required, a continuous process is usually used. Tubular evaporators are the first choice where they are applicable.

Throughput, viscosity, solids content, fouling tendency, and foaming tendency will determine the type best suited and whether the design requires circulation.In general, forced-circulation evaporators are more expensive than natural-circulation, but in some cases the higher heat-transfer coefficients allow a small enough evaporator to be used that capital costs are about the same or lower.

Where the product is difficult to handle due to extreme temperature sensitivity, high viscosity, heavy solids, or a high tendency to foul, a technology such as the plate-and-frame or agitated thin-film evaporator maybe required.

Literature Cited

WILLIAM B. GLOVER is an engineering consultant and former vice president for process engineering at LCI Corp. (P.O. Box 16348, Charlotte, NC, 28297; Phone: (704) 398-7878; Fax: (704) 392-8507; Email: [email protected]). He was with LCI for 40 years and is a specialist in process design, distillation and heat transfer in the food, pharmaceutical, chemical and polymer industries. He earned his BChE at North Carolina State Univ., is member of AIChE, and is a registered professional engineer in North Carolina