As today’s residual chemical requirements in consumer goods become more stringent, an emphasis has been put on cleaning up and “polishing” the processes used to produce these products. In order to reach these goals effectively, an evaporation process may require the use of additional stages and equipment, increasing both capital cost and space requirements.

A thin film evaporation process will, therefore, often have an external “pre-heater” (shell & tube, plate & frame, etc.) installed upstream. This provides additional heating surface area and allows the evaporator to focus on concentration/ evaporation as opposed to reaching boiling temperature. The drawbacks are additional footprint, pressure relieve valves, piping, control loop, steam traps, and heat losses to environment. Additionally, a flash tank may be required depending on the superheat added to the evaporator feed stream to decrease entrainment.

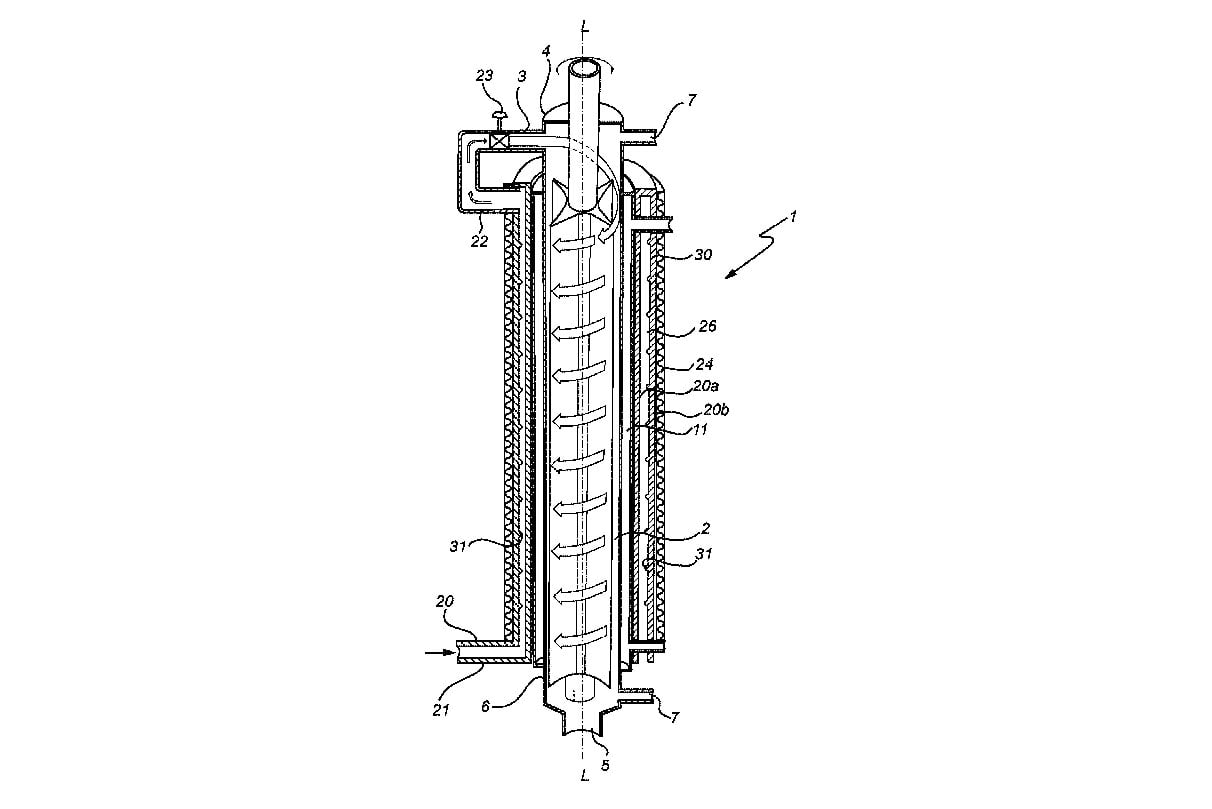

Recognizing the need for further refined end products and chemicals, LCI has tested, designed, and patented a new “Double Jacket Thin Film Evaporator” which incorporates a flash tank, pre-heater, and thin film evaporator into one asset. The unheated feed enters at the bottom of the exterior jacket. The exterior jacket can consist of pipe coil or baffled cylindrical jacket. The hot oil pumped into the middle jacket to provide heat to both the exterior jacket and evaporator shell. The pre-heated feed enters the evaporator at the top and flashes into the unit. The vapors and concentrate travel co-currently through the unit and exit at the bottom surge tank. This space and capital saving design cuts down on installed equipment and simplifies operation by combining multiple unit operations into a single unit. Energy losses are also minimized by containing the hot oil in the middle jacket.

LCI has supplied thin film evaporators worldwide from our Charlotte, NC location since the 1960s and continues to develop novel thermal separation solutions. Our comprehensive test center is open for your pilot plant trials and process scale up. Contact your process expert at LCI for assistance in picking the right equipment for your evaporation process.