- Home

- Sludge Drying

- Thin Film Sludge Dryer

Linear Dryer

Linear Dryer

How it Works

The Linear Dryer is a Second Stage Dryer which can be added to previous drying steps, typically The Thin Film Dryer. The Linear Dryer is designed to accept sludge past the “sticky” phase and is usually fed at 60-70% DS then dries to a content of 90%+ DS.

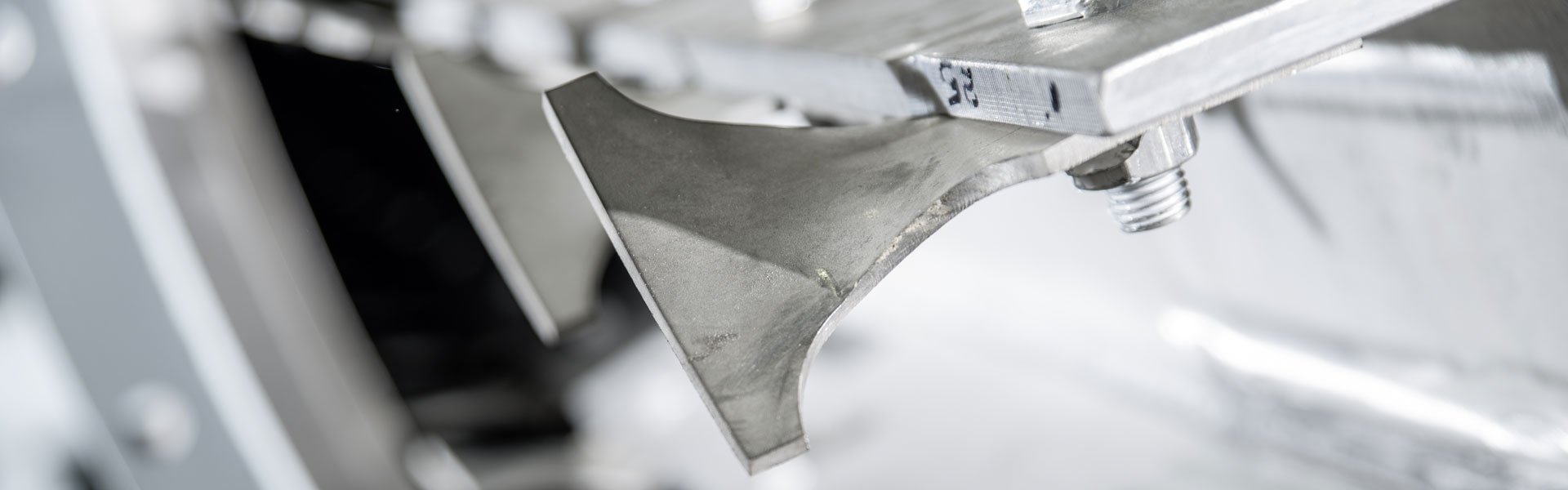

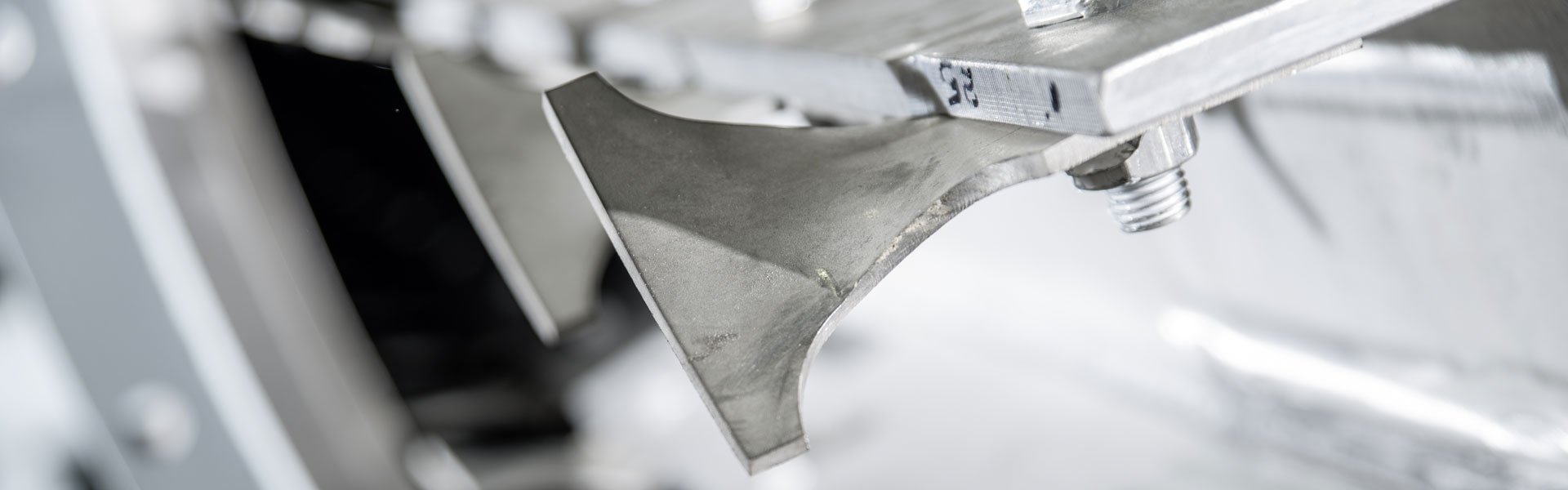

The operation of the Linear Dryer is simple. Partially dried sludge is placed into the linear dryer. Inside the dryer the sludge is in contact with a heated wall which evaporates of the moisture from the sludge. A specially designed auger/blade system mixes and conveys the sludge through the dryer to the discharge.

The slow rotating auger offers the advantages of low dust generation, maintaining granule shape and low energy consumption.

Applications

The Linear Dryer is designed to augment previous drying steps, typically the Thin Film Dryer. It is designed dry sludge to 90%+ and typically used for Agricultural (Class A) applications or thermal destruction processes which require high DS contents.

Application Examples:

- Requiring a nice granular, low dust product

- Increased evaporation capacity of an existing drying system by adding the second stage capacity

- Allowance for different end products from the same system, For example, the Thin Film Dryer can be used to dry to 60-70% DS for Landfilling and then the Linear Dryer added to dry to 90% for Agricultural (Class A) usage.