- Home

- Evaporation

- Laboratory Equipment

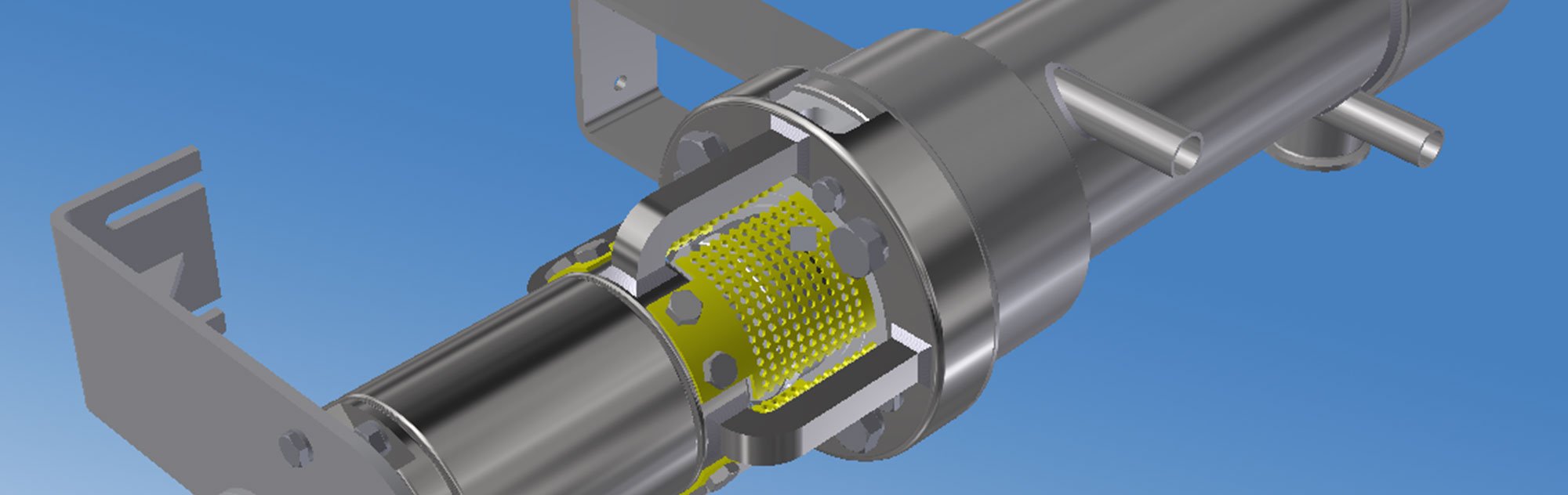

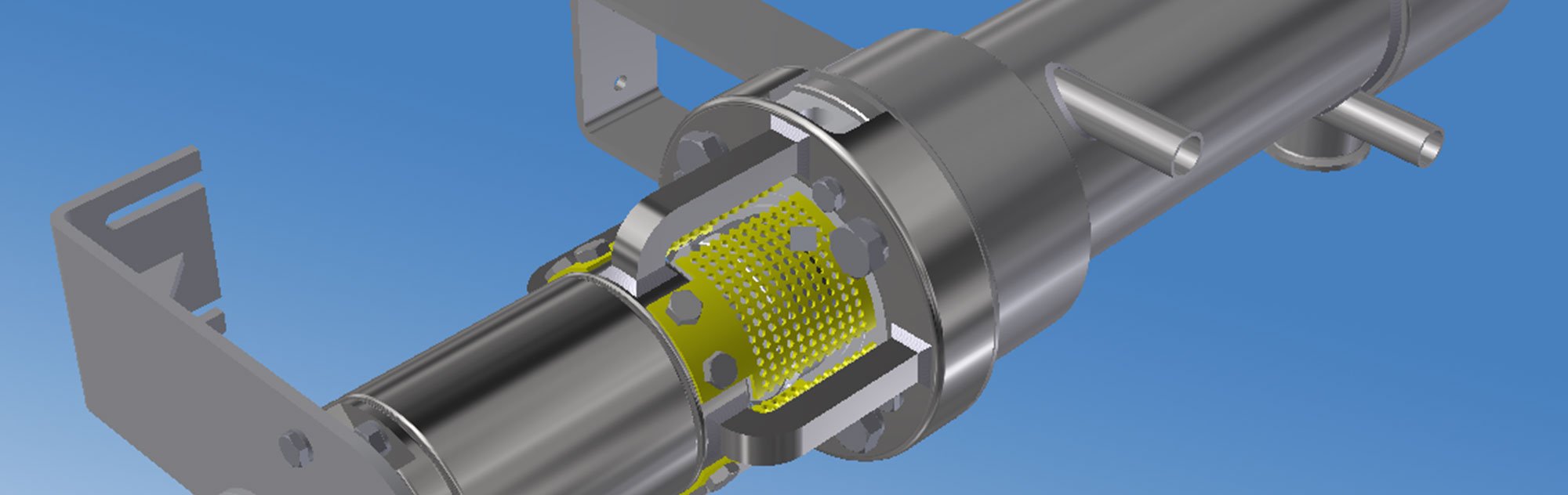

Sanitary Super LabVap System

Sanitary Super LabVap® System

Fast Facts

- Heated Surface Area: 0.5ft2

- Material of Construction: 316 SS process wetted parts

- Process Area P/T Rating: FV to ATM @ 650°F

- Jacket P/T Rating: 150psig @ 365°F (steam), 100 psig @650°F (liquid)

- Feed Rate: 2-40 lb/hr (typical)

- Viscosity: 8,000 cP max (typical)

Features and Benefits

- Test or Lease to quickly and efficiently determine if development of your product is possible with LCI thin film evaporation

- Designed for CIP requirements

- Minimal product required for operation

- Operate under vacuum as low as 1 Torr

- Quick disassembly/assembly for ease in cleaning and inspection

- Horizontal configuration allows for greater residence time control

- Explosion-proof

- Engineering support for set-up, process assistance, parts, and service

- Ready for connection to your utilities

See how it works with common applications.

Literature

Sanitary Super LabVap Brochure

Labvap Thin Film Evaporator Technical Bulletin

Evaporator Type Comparison Chart

Thin Film Evaporator Design

Thin Film Evaporator Operation