LCI High Viscosity Processors utilize transported thin film technology to evaporate products in the viscosity range of 50,000 to 15,000,000 cP. By applying transported flow rotor designs, High Viscosity Processors are capable of finishing various polymers, resins, and plastics, concentrating highly viscous food products, initiating and devolatizing various reactions, and processing various other viscous separations. High heat and mass transfer rates, combined with continuous, reliable operation make LCI High Viscosity Processors the perfect evaporation solution.

The Filmtruder and Viscon are vertical high viscosity thin film evaporators. Transport blades help move viscous materials down the heated evaporator wall while rapidly renewing the surface to allow volatile components to evaporate quickly and effectively. The Filmtruder and Viscon are capable of handling materials from 50,000 cP to 10,000,000 cP.

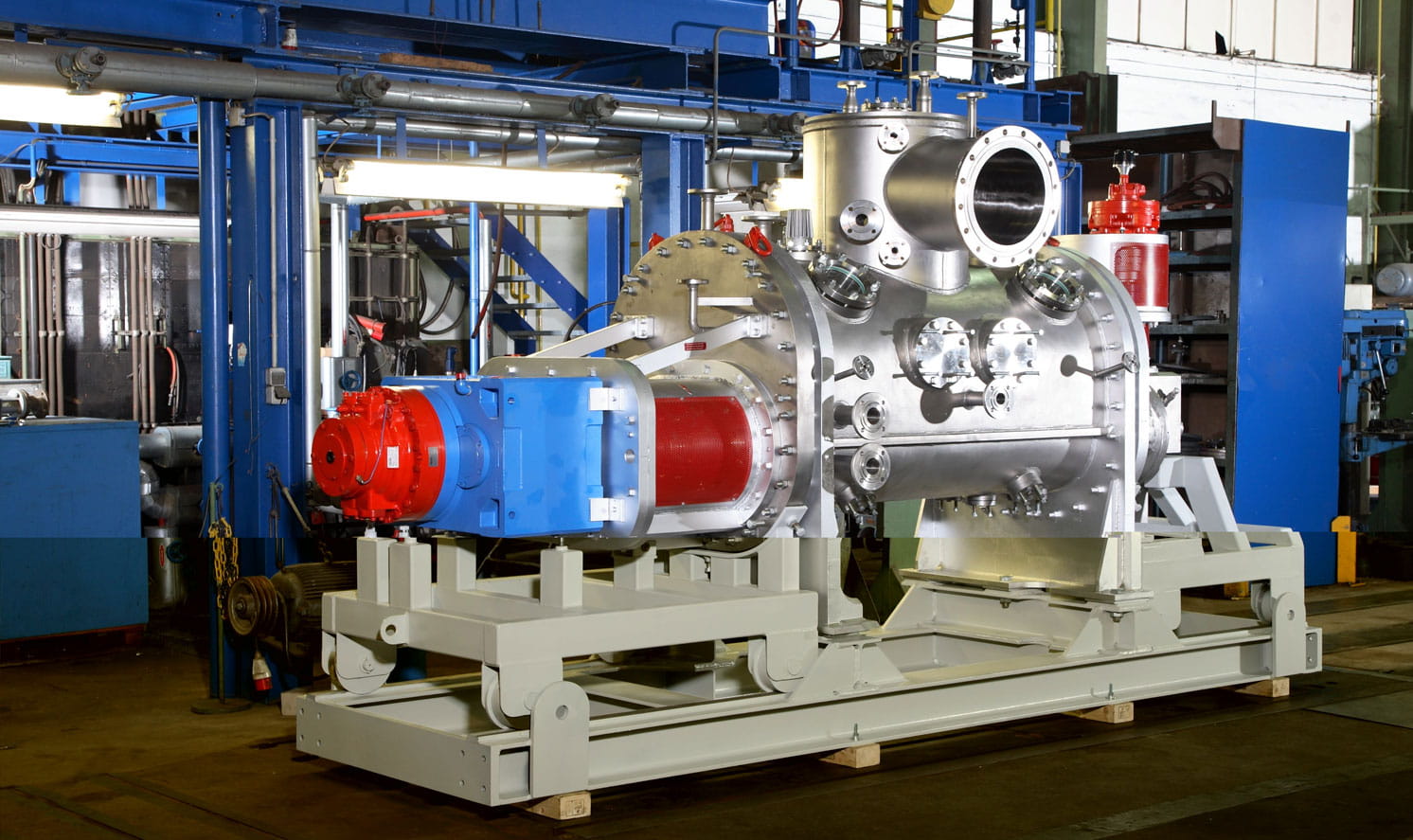

Developed by our partner, Buss-SMS-Canzler, the Large Volume Processor (LVP) is a horizontally arranged heated reactor, with either one or two rotating shafts, and employs both batch and continuous operation designs. The LVP is used for mixing, reaction, and devolatilization, often all in one machine. A highly capable process solution, the LVP can handle viscosities of up to 15,000,000 cP, while being able to handle certain processes from starting material (melt) to final solid form.

High Viscosity Processing

Positioning of Viscous Concentration, Devolatilization, and Reaction Technologies

Evaporator Type Comparison Chart