LCI Thin Film Dryers concentrate slurries, suspensions, and solutions such as catalysts, salt solutions, and crude glycerin to a dry flowable powder or cake. This is done with indirect heat transfer and mechanical agitation of the thin product film under both vacuum and atmospheric conditions. LCI offers a range of drying solutions utilizing both vertical and horizontal thin film drying technologies.

Utilizing indirect heat transfer and thin film agitation eliminates the need for large volumes of hot air to dry the product. This in turn can reduce costly air treatment equipment and systems. The short residence time and minimal product hold up is ideal for continuous processes with heat sensitive materials. Our variety of dryer offerings and test center allow us tailor a drying solution to your process.

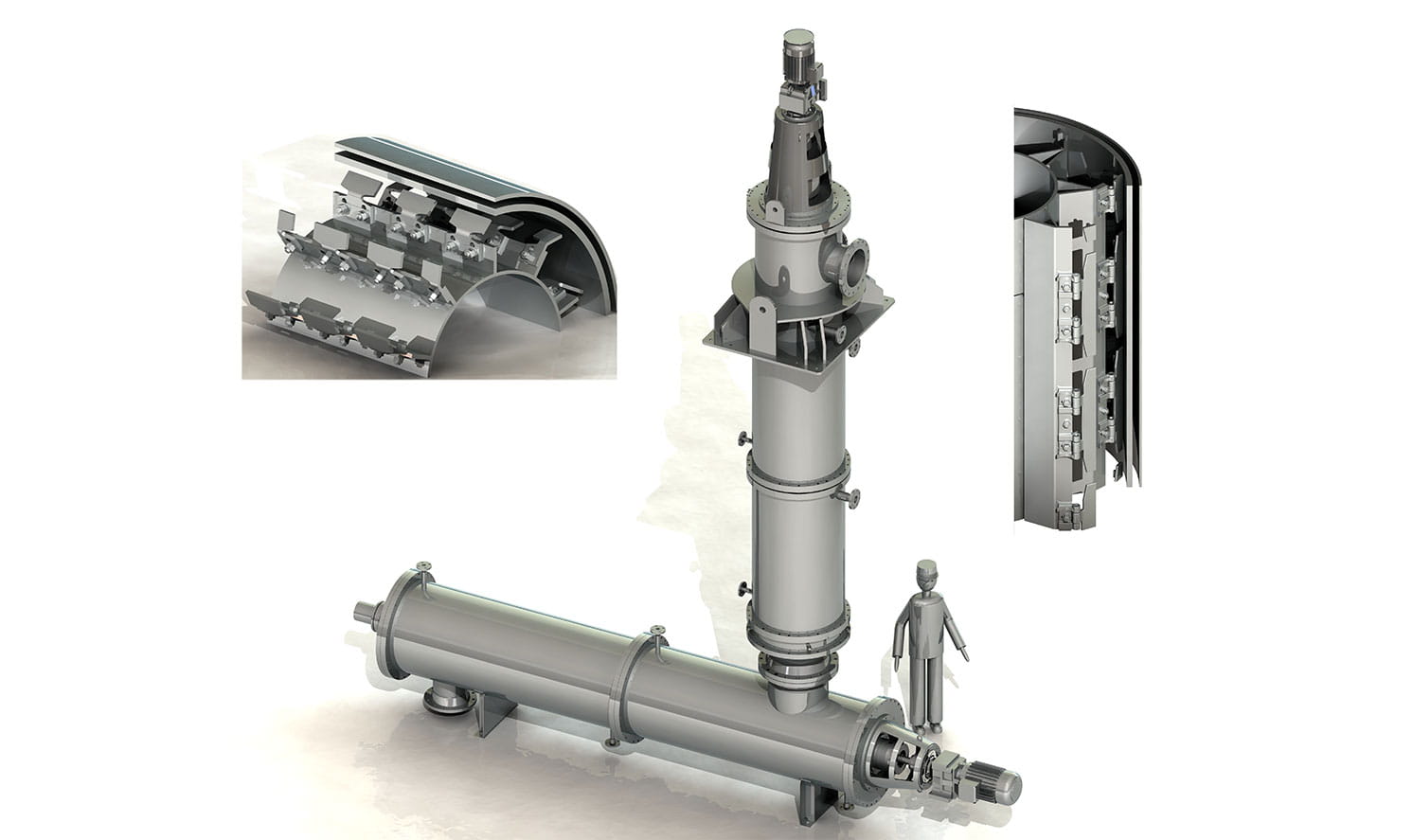

A horizontal thin film dryer utilizing a heated wall and rotor with bolt on transported flow and wiping blades. As with a vertical thin film dryer, the dryer does not operate with a product level within the shell, and product is only spread in thin film at the heated wall. This allows for minimal product hold up within the evaporator. Residence time and conveying can be adjusted by configuring the bolt on blades through testing, and moisture levels of less than 1% can be achieved at the discharge of the evaporator. Common applications include catalysts, intermediate pharmaceutical products, various food products, and sludges.

A vertical, counter current, thin film dryer that uses hinged and weighted pendulum blades to mechanically agitate the product. The clearance of the blades to the heated wall allow separation of volatile components, while preventing fouling of the heated wall. As the product moves down through the evaporator, the feed slurry moves through a paste like phase, and then finally to the powder phase, where the pendulum blades break larger particles and is discharged via gravity. Discharge is usually handled by an air lock system. Common applications include agrochemicals, waste water, solvent recovery, and catalysts.

Thin Film Drying Technologies

Thin Film Drying

Drying Summary